OptiCalender Multinip

Profitable and safe investment - also in the future

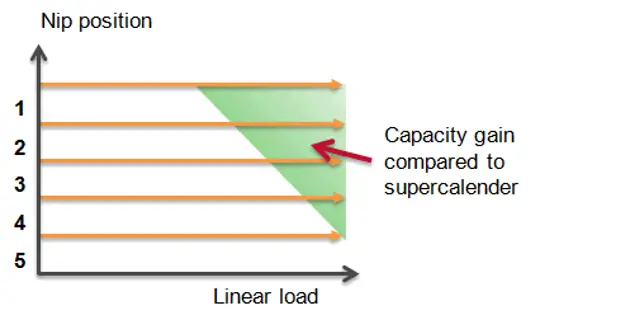

Valmet’s multinip calender is used both in off-line and on-line applications. The OptiCalender Multinip loading principle makes it possible to load all nips with the same linear load, resulting in efficient plasticization of paper in the very first nips. Profiling performance is affected by the number of control zones on deflection compensated bottom and top rolls.

High end-product quality

Reliable operation and high efficiency

Easy operation and safe maintenance

Profitable and safe investment

The multinip calendering technology represents the spearhead calendering technology for the paper industry. This claim is backed by over 50 references sold. Valmet's innovative OptiCalender Multinip with two stacks enables calendering of top quality printing papers even at very high speeds. Together, OptiCalender Multinip and OptiCalender Multinip with two stacks are Valmet's unrivaled multinip calendering solutions meeting the needs of all paper grades.

Want to talk to our calendering experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our experts

High end-product quality

Wide range of process parameters gives more flexibility to produce different grades. The aimed quality level will be reached by combining the effect of temperature and linear load. It is possible to design the calender so that there is a space reservation to add rolls in the future. A partial nip mode is also a possibility.

Even profiles and desired surface quality can be reached with OptiCalender Multinip's accurate loading and even surface temperatures of thermo roll and stable temperature control of heating system. Also intermediate roll levers and profiling with deflection compensated rolls drives to high product quality.

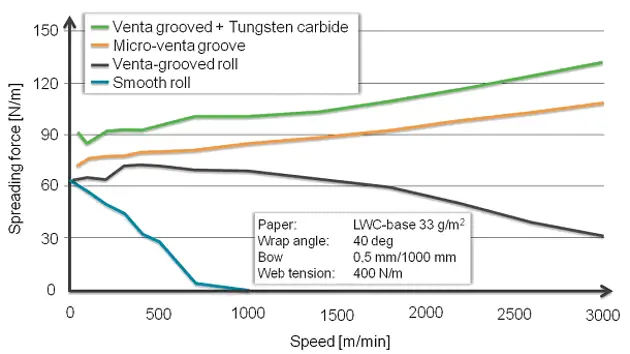

Understanding the fundamentals behind functional spreading of paper web is demanding and requires a long experience.

Reliable operation and high efficiency

High time-efficiency is a combination of many factors. High quality and durable components ensure e.g. that spare parts are available also in the future and the roll covers are of top quality. Thermo roll dimensioning according to FKM norms, i.e. thermo rolls dimensioned to withstand the process parameters. Comprehensive monitoring of calender systems and equipment minimizes unplanned shut-downs.

High performance tail threading is a key element for high productivity of the paper machine. Valmet has a large numbers of on-line multinip calender tail threading in both Valmet’s own and competitors calenders. Tail threading performance is developed continuously by running trials in tail threading pilot machine.

In off-line calender efficient splicing is a must. Both unwind and wind-up splicing sequences are automatic.

Easy operation and safe maintenance

The multinip calenders are easy to access for maintenance. User-friendly automation provides real time info about the machine status. All information - including history – is easy to find. Functions are visualized symbols, whenever possible - No codes in error messages. User-friendly automation helps users recognize, diagnose, and recover from errors.

Planned and instructed maintenance actions

Designed for safe operation

Profitable and safe investment

Strong reference base tells its powerful story. Wide operating window and upgrade readiness are functions that make OptiCalender Multinip profitable also in the future. Process and equipment support is available to further improve your calendering process.

OptiCalender Multinip with two stacks calender was developed to meet the demands of high-speed calendering on top quality printing papers.

Former one-stack multinip calender OptiLoad and two-stack OptiLoad Twinline have been unified in the OptiCalender family as OptiCalender Multinip.

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsHow do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreLearn more about the services and automation solutions for calenders

Explore our latest board and paper press releases

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China

- Sep 5, 2024Valmet to start change negotiations in Finland in its Paper business line’s Board and Paper Mills business unit

- Aug 16, 2024Valmet and Spinnova Plc sign a partnership agreement regarding process equipment for textile fibre production

- Aug 1, 2024Valmet closes the agreement to acquire majority shares in FactoryPal, a subsidiary of Körber

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States