Valmet headboxes

Excellent quality and high profitability

Valmet headbox family comprises an optimal selection of paper machine headboxes to meet various production requirements in paper and board making. New innovative headbox solutions, combined with the precise dimensioning know-how of today, raise the performance of your paper machine to a totally new level. Valmet headbox family provides excellent end-product quality, higher productivity, lower life cycle costs and a secure investment.

Discover Valmet headbox selection

Get to know our two headbox product families: OptiFlo headboxes and IntelliJet V headboxes. Click on the links below to read and find out more on our headbox solutions.

Want to talk to our headbox experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our headbox expertsSuperior performance with Valmet headboxes

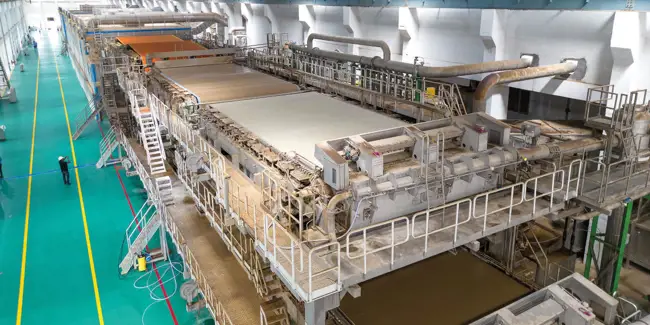

The headbox plays a key role in producing high-quality paper and board products. Designed to produce perfect visual appearence with good profiles accross the entire machine, Valmet headboxes deliver improved paper quality and increased machine productivity. Production and quality targets can be reached more quickly after start-up - and with fewer web breaks and less broke. This means high machine efficiency and a rapid return on your investment.

The keywords of a properly functioning headbox are uniformity and profiles. The hydraulic performance of the headbox mainly determines the properties of the paper. The headbox controls the web’s profiles and helps to establish paper properties such as formation.

Qualities of a great headbox include distributing stock uniformly across the forming section, without disturbances, and imparting sufficient turbulence to the flow to keep the fibers dispersed. Equally important factors are that the headbox is easy and simple to operate and remain clean during operation.

Headbox solution for your specific need

Valmet headbox family offers all application methods and all paper machine sizes available - Fourdrinier, layering Fourdrinier, Gap, and layering Gap headboxes as well as the new innovative aqua layering technology that makes it possible to produce a two-layer sheet with very good layer coverage using only one headbox and forming unit.

Valmet Paper Technology Center provides the world's most comprehensive offering of testing and piloting services to paper and board manufacturers worldwide. We offer the opportunity to experiment and develop paper and board products and processes without having to put your own production on hold. This is a very cost-efficient compared to expensive tests in your own production.

Our pilot facilities have the entire paper machine process covered providing customers with excellent service and reliable results to support investment decisions. Your R&D team is warmly welcome to join our experts to develop the optimal configuration to support your papermaking demands also in the future.

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsLearn more about OptiFlo headboxes

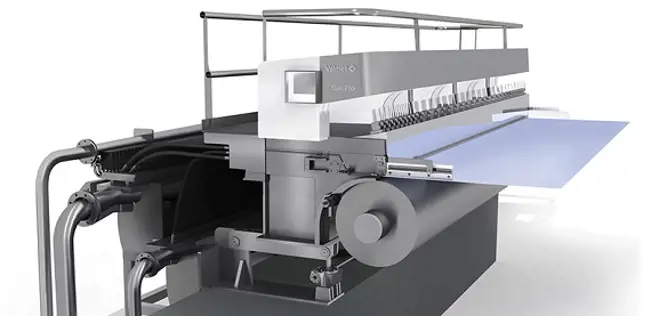

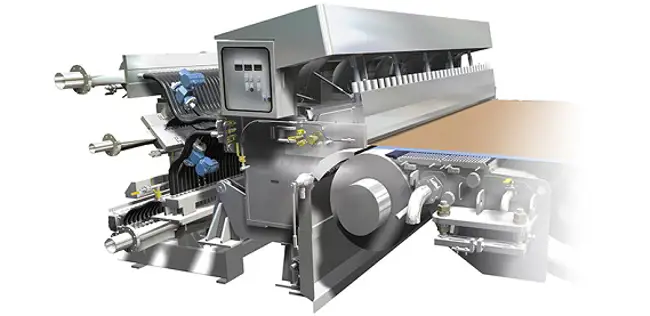

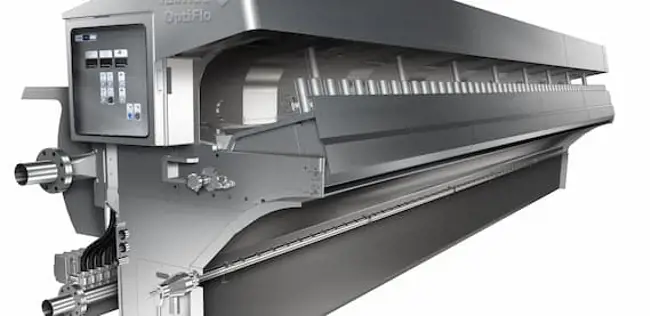

The OptiFlo headbox family introduces a new level of performance, with modular construction developed to meet the increasing productivity and quality requirements of high-quality paper and board machines. The OptiFlo headbox family combines proven technology with new ideas.

OptiFlo's advanced design simplifies later upgrades, making possible to handle changing production needs or introduce new control technology with minimal disruption to production. The headbox ensures optimum utilization, even if production or quality targets change.

Planning a grade conversion?

The world is changing fast; the consumption of newsprint and printing paper is decreasing and the consumption of containerboards or cartonboards are increasing. An old paper machine can be updated with a grade conversion rebuild to produce more profitable products. Turn a new page for your paper machine with the help from Valmet.

Discover moreHow to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookServices and automation solutions for headboxes

Explore our latest board and paper press releases

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 8, 2024Discover Valmet MTC Wizard at Tissue Innovation Days 2024: the latest technology enhances Client benefits in Tissue Folding

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India

- Jun 19, 2024Valmet receives the second order of converting lines to Metsä Tissue in Mariestad, Sweden

- Jun 13, 2024Valmet and Flootech enter partnership to advance water treatment for the board, paper and tissue industry

- May 30, 2024Valmet enters joint venture with Körber to advance the digital offering to the tissue industry

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China