Valmet cylinder drying

Maximum efficiency with minimum energy consumption

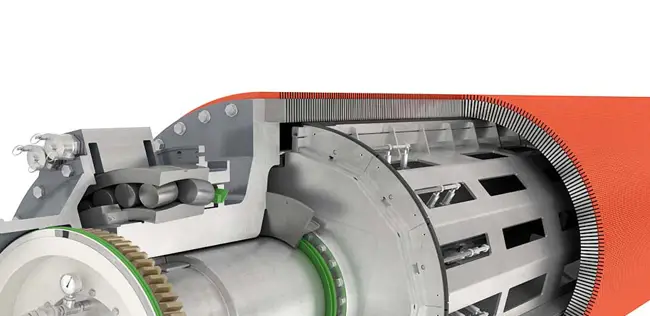

In papermaking, it is vital to ensure maximum drying efficiency with minimum energy consumption. Valmet cylinder drying portfolio is able to provide perfect solutions for all customer needs regardless of your grade, machine speed, or basis weight. Our offering also includes rebuilds, components, and services, in addition to various drying analyses and optimization services.

Discover Valmet's cylinder drying selection

Get to know our cylinder drying product family OptiRun dryer section and Runnability Systems. Click on the link below to read and find out more on our drying solutions.

Proven technology for all needs

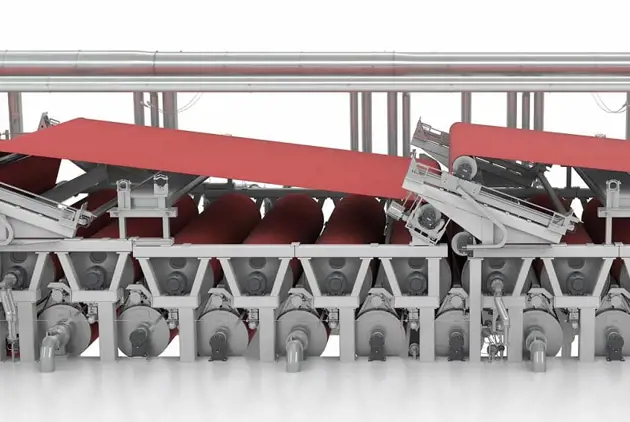

Valmet cylinder drying family features optimized steam consumption with effective ventilation and heat recovery for energy-efficient operation. As the efficiency of the entire machine is affected by the runnability of the dryer section, open draws are minimized and the wet web is well supported at the beginning of the dryer section. This ensures trouble-free web transport and production, regardless of machine speed or grade.

Controlled web shrinkage and stretch optimize end-product quality. Optimized geometry of single-fabric and double-fabric sections target even moisture profiles and flatness with minimum energy input.

Want to talk to our drying experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our experts

Do you want to know more about Valmet's compact concept?

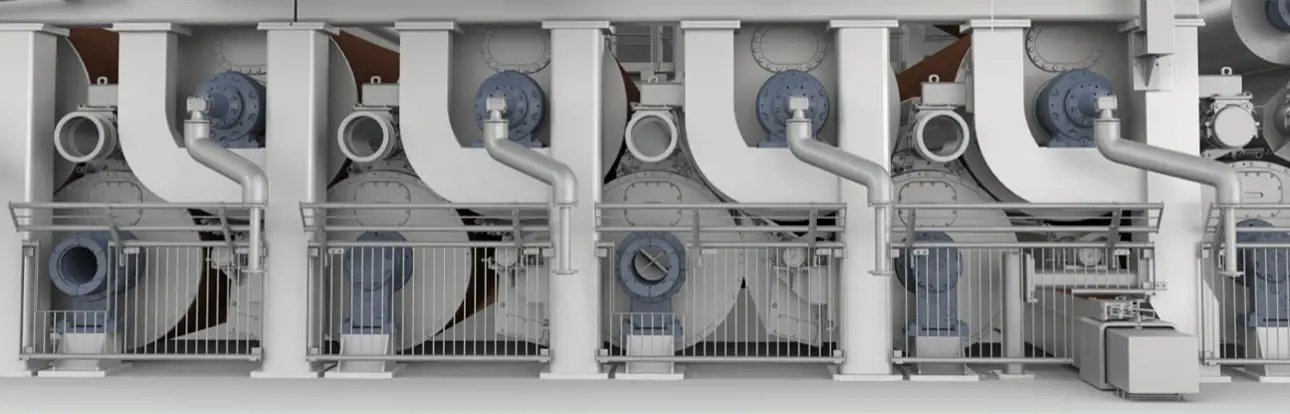

OptiRun compact concept is a game-changer in paper machine dryer sections. Ensuring good runnability, improved drying efficiency and excellent tail threading, this is the biggest change in drying section design in the last 35 years.

Read the articleCustomer story: Superb dryer section for APP Jingui BM2

APP Jingui BM2 is a coated cardboard production line, with a web width of 8,850 meters and a design daily capacity of nearly 4,200 tonnes. According to APP, Valmet’s integrated design in the drying section has allowed overall energy savings. This includes the compact and optimized dryer cylinder and guide roll arrangement, with Valmet Runnability Systems, OptiAir Hood and other systems, which have all worked well together. Watch the video to learn more.

Learn more about the services for dryer section

Interested in pilot trials?

Get in touch with our pilot trial experts to discuss how you could benefit from our pilot trial services.

Contact our pilot trial expertsHow to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookExplore our latest board and paper press releases

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States

- Jul 8, 2024Discover Valmet MTC Wizard at Tissue Innovation Days 2024: the latest technology enhances Client benefits in Tissue Folding

- Jul 2, 2024Valmet to supply a high-capacity winder to Wuzhou Special Paper in China

- Jun 26, 2024Valmet to supply both a papermaking line and a paper machine rebuild to a customer in Asia-Pacific

- Jun 25, 2024Valmet to deliver a tissue machine to Andhra Paper in India

- Jun 19, 2024Valmet receives the second order of converting lines to Metsä Tissue in Mariestad, Sweden

- Jun 13, 2024Valmet and Flootech enter partnership to advance water treatment for the board, paper and tissue industry

- May 30, 2024Valmet enters joint venture with Körber to advance the digital offering to the tissue industry

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China