Emissions reduction and control

Environmental protection through paper mill emissions reduction and control

Environmental protection is essential in today’s world – for the sake of everyone’s well-being. Emissions management is a key issue for pulp and paper mills. Gaseous emissions and carbon footprints must be reduced to comply with legislative and regulatory environmental requirements. Environmentally sound operation is also fundamental for disturbance-free production. By promoting silent and practically emission-free production, paper mills can also improve their image and be recognized as responsible members of the community.

Valmet has developed technologies that help mills achieve all of the above targets. Our solutions are well-suited for pulp, paper and board machine lines, power plants, and recovery boilers.

Efficient emission control with lots of references

Paper machine noise levels have been reduced to meet ever-tightening requirements. For the reduction of sound emissions, we can supply optimal layout solutions and multiple products, like its Valmet Sound Attenuators for muffling a variety of sound frequencies. For better indoor air quality, we have high-efficiency droplet and dust separators that belong to the OptiAir Environment family. For gas emissions control, we offer solutions like CO2-free coating air drying. Our information management systems, meanwhile, enable mills to react and respond rapidly to process disturbances.

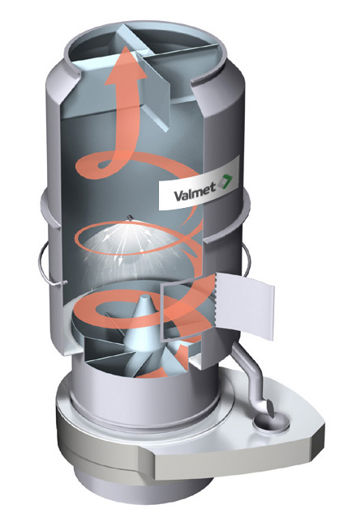

DSA droplet separator

Decreasing of droplet and humidity emissions through Droplet Separators.

Valmet Sound Attenuators

Sound Attenuators for low and high frequency attenuation facilitate low mill noise levels, including city-based mills.

Explore our latest board and paper press releases

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China

- Sep 5, 2024Valmet to start change negotiations in Finland in its Paper business line’s Board and Paper Mills business unit

- Aug 16, 2024Valmet and Spinnova Plc sign a partnership agreement regarding process equipment for textile fibre production

- Aug 1, 2024Valmet closes the agreement to acquire majority shares in FactoryPal, a subsidiary of Körber

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States