NOx Reduction

NOx, one of the most significant air pollutants in flue gas, causes smog and acid rains when released into the atmosphere, leading to health and environmental hazards. With the common concern over NOx emissions growing, the global trend is to tighten its emission limits. Valmet provides you with a wide range of applications for NOx emission reduction. The most optimal method is always selected case by case. Read more about out SCR, SNCR and Scrubber solutions.

Selective Non-Catalytic Reduction - SNCR

Selective non-catalytic reduction (SNCR) method is a cost effective solution for secondary NOx emission control. The SNCR method is an ammonia or urea injection system that reduces NOx emissions. NOx reduction achieved with this method depends on the boiler design and load. Typical reduction varies from 20% to 70%.

Reducing NOx emissions In SNCR, ammonia or urea is injected straight into the furnace or cyclone inlet and mixed with the hot flue gas. Ammonia reacts with nitrogen oxides to produce water and nitrogen.

Selective Catalytic Reduction - SCR

Applications that require a high NOx reduction level, the most feasible technology is often Selective Catalytic Reduction (SCR) as it provides a reduction rate up to 95%. In SCR of NOx nitrogen oxides are reduced to water and molecular nitrogen in an SCR reactor. The purpose of the catalyst is to speed up the reaction.

The SNCR and SCR technologies can also be used together to ensure low emission levels and minimize the catalyst size.

NOx Scrubber

Valmet NOx Scrubber is the best solution when low NOx emissions are required, process conditions are challenging for conventional methods such as SNCR or SCR. The scrubber suits well for recovery boilers, lime kilns, incinerators, waste-to-energy plants, refineries and other industrial applications.

A true multi-emission control scrubber

NOx scrubbing is based on a technology where NO (nitrogen monoxide) in flue gas is oxidized with the help of an oxidant such as O3 or ClO2 to a soluble form of nitrogen oxides (NO2 and N2O5). NO2 and N2O5 are then washed from flue gas by an alkaline scrubbing liquid in a conventional flue gas scrubber.

As the absorption process is like that in a conventional scrubber, Valmet DeNOx Scrubber can act as a multi-emission control scrubber and reduce other soluble components from flue gas such as SO2, HCl, NH3 and dust. Existing scrubbers can be modified to reduce NOx emissions. Also, heat and water recovery can be integrated with the Valmet NOx scrubber process.

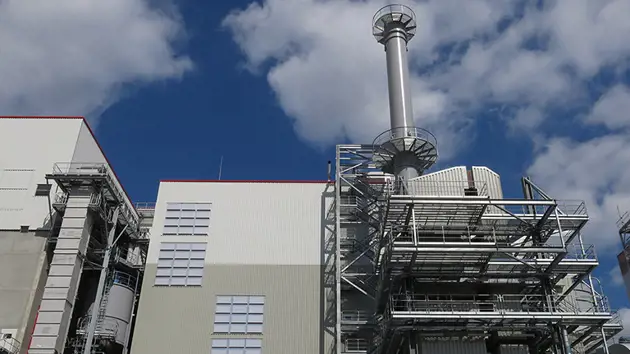

Customer Case HOFOR, Amagerværket, Denmark

Valmet CFB technology is applied in this large biomass fired boiler located in Copenhagen city center. The boiler is equipped with both, SNCR and SCR technologies to reach ultra-low NOx and NH3 emission levels in the stack. The catalyst is located on the high dust side before other flue gas cleaning equipment and its performance is followed regularly with laboratory tests to ensure high NOx reduction rate all the time. Vaporized ammonia is used to reach effective mixing between flue gas and ammonia.

Start-up in 2019

Fuel: Wood chips

Solution delivered:

- High-dust Valmet Catalytic Reduction

- Valmet CFB Boiler 460 MWth

Related Pages

Our expertise is at your service

Our focus is to bring your performance forward. Our expertise in sustainable energy production and emission control is at your disposal. Get in touch with our specialists through your local Valmet office, or the link below.

Contact us