Valmet Pyrolyzer

Valmet Pyrolyzer is a thermal conversion technology for liquid biofuels, biochemicals and plastic chemical recycling. It is unique as it combines the advantages of fast pyrolysis to the use of catalysts according to the end product chemical composition need.

Scalability

Unit size can be increased to handle large volumes bringing CAPEX savings

High product quality

Accurate control of residence time and temperature together with use of catalyst

High product yield

Achieved through optimized process conditions

Optimized energy concept

Allows by-production of steam, heat and power

Sustainability

Valmet pyrolysis solutions reduce >80% CO2 compared to fossil fuels or fossil biochemicals

Safe to use

High level of automatization and separation of process parts via inertization

Fast pyrolysis and catalytic pyrolysis technologies for high-value products

Valmet Pyrolyzer is a comprehensive solution that seamlessly integrates into the overall energy concept, complete with automation. This integration minimizes risks for investors, as Valmet assumes both technology and equipment responsibilities.

Valmet Pyrolyzer turns solid biomass into high value liquid fuels and chemicals. We can offer the entire plant solution including automation, service and maintenance.

Valmet Pyrolyzer is used in the following applications:

Transport biofuels

Catalytic pyrolysis of biomass can produce biocrude for sustainable fuel production. In our large pilot plant, we are able to test different feedstocks and provide large quantities of biocrude for downstream testing. In the future, your car may run on biofuel made from forestry residues!

Biochemical production

Pyrolysis liquid is used as a raw material for renewable chemicals. We are currently delivering an industrial pyrolyzer for biosolvent production, while processes are being developed also for other biochemical production pathways.

Plastic chemical recycling

Pyrolysis is able to convert plastic waste into raw material for new plastic. This together with plastic mechanical recycling allows to increase the amount of recycled material. We are currently running pilot tests with various plastics.

World-class testing facilities

|

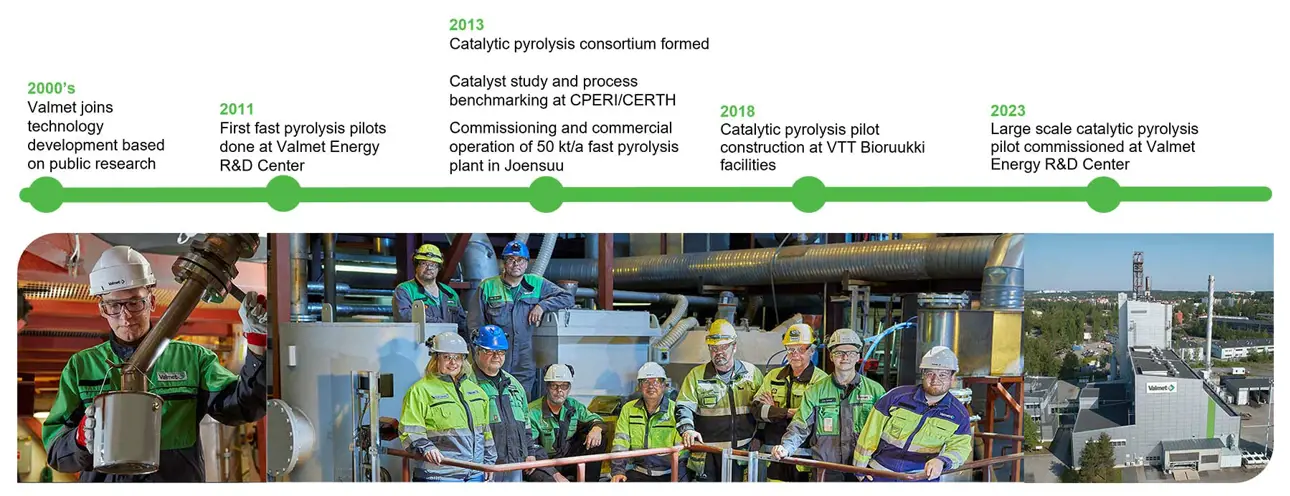

Valmet has built a large pilot plant in its facilities in Tampere, Finland. The unit feedstock capacity is 400 kgDS/h and it produces 2,5 t/day of Catalytic Pyrolysis Oil (CPO) also called biocrude. The plant is able to test different feedstocks and produce CPO for downstream refinery testing. |

Read more

Our expertise is at your service

Our focus is to bring your performance forward. Our expertise in sustainable energy production is at your disposal. Get in touch with our specialists through your local Valmet office, or the link below.

Contact us