Integrating IT and OT systems: A crucial step for digital transformation

Dec 12, 2024

Automation technology and IT tools are becoming increasingly connected, making operations more transparent and efficient. This shift, known as IT/OT convergence, plays a critical role in enabling digital transformation across industries.

But what does it mean to connect operational technology (OT) and information technology (IT) systems, and what opportunities can it bring to your business?

We spoke with Arnold Präsent, Senior Manager at Valmet and Teemu Kiviniemi, Solution Manager for Valmet DNA, to explore how this shift is transforming industries and how companies can navigate their digitalization journey.

Arnold Präsent, Senior Manager at Valmet and Teemu Kiviniemi, Solution Manager for Valmet DNA.

What is IT/OT convergence, and why does it matter?

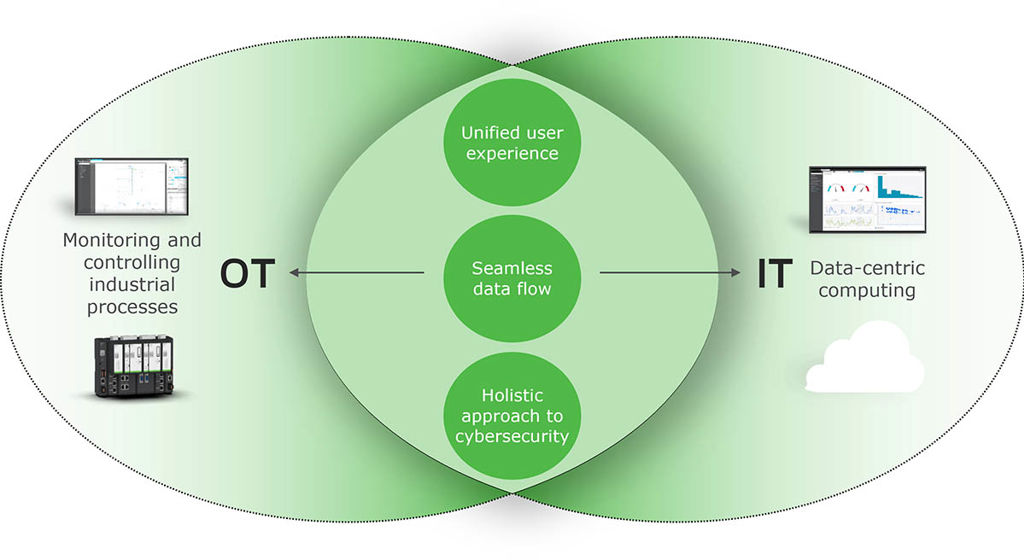

IT/OT convergence refers to the integration of IT systems—used for data-centric computing—and OT systems—which monitor and control industrial processes.

Traditionally, automation systems operated as heavily secured islands. As Arnold puts it, "They were locked down heavier than Alcatraz. Nothing in, nothing out." While this ensured security, it made sharing data digitally outside the OT system impossible. Now as data sharing has become essential, we have to open these systems while still maintaining security.

Simply put: If you're aiming for autonomous operations and want to leverage AI in production processes, you can't rely on a closed automation system—your platform needs to provide data via open and secure interfaces.

Teemu shares: "IT and OT will never be completely separate again. There's no going back—the convergence will march on."

Key benefits: Improve transparency, efficiency, and cybersecurity

Integrating your production processes with business technologies—like data analysis tools and your enterprise resource planning (ERP) system—creates a seamless data flow. You get a comprehensive view of operations, making it easier to identify trends, solve issues and make smarter, more informed decisions.

Connecting your IT and OT systems also creates optimization opportunities across the entire value chain. It helps you increase production flexibility and maximize efficiency, which ultimately leads to financial gains. Applying IT methodologies to OT data—like collecting, contextualizing, and analyzing—further streamlines workflows, reduces complexity, and boosts operational agility.

Plus, merging systems allows you to take a unified approach to cybersecurity, ensuring both digital and physical assets are protected against emerging cyber threats. With the NIS2 Directive calling comprehensive security across both IT and OT systems, it highlights the importance of a holistic approach. As Teemu notes, "NIS2 will bolster IT/OT convergence," strengthening cybersecurity across the entire production facility.

Integrating your production processes with business technologies allows unified user experience, seamless data flows and holistic approach to cybersecurity.

Steps to connect your IT and OT systems

Build a strong foundation

Before jumping into the technology behind connecting your IT and OT systems, make sure you're ready for the change and understand the value it can bring. "You need organizational maturity, alignment from leadership, and the right processes and change management in place before focusing on technology solutions," says Arnold.

Without this foundation, even the best technical solutions are unlikely to succeed. Teemu advises: "IT/OT convergence is a natural progression. There's no need to rush in with a big budget—it's about taking meaningful steps when the time is right."

Prioritize cybersecurity

"Cybersecurity is one of the most critical and prominent areas where IT and OT must align," says Arnold. While OT focuses on operational aspects—like field communication, production process data, and cloud integration—IT handles business and office applications like your ERP system.

Cybersecurity unites IT and OT by aligning both sides toward the shared goal of creating secure systems across the board.

Clarify roles & responsibilities

Clear roles and responsibilities are crucial when merging IT and OT systems, especially with multiple vendors. Document these roles—covering infrastructure, cybersecurity, and services—to ensure smooth collaboration. "As IT and OT converge, IT will take on more responsibility,” says Teemu. “This shift often moves from OT to IT."

Collaboration is key—both IT and OT teams must understand each other's needs. "What's relevant for IT and OT systems might be the same, but it needs to be handled differently," says Arnold. For example, maintenance on IT office systems can be done at night when usage is minimal. However, maintenance on OT control systems can disrupt 24/7 operations and must be planned well in advance, often during annual plant shutdowns.

Don't do it alone

A successful IT/OT convergence strategy requires strong partnerships. "No one can do it alone," says Teemu. "If you're not working with partners, the process becomes slow and costly."

Valmet DNAe, for example, was built with IT/OT convergence in mind, offering seamless connectivity from sensors to the cloud via edge technology and industrial-standard interfaces. This integration enables enhanced digital intelligence, paving the way for AI-powered tools at every level.

With a security-by-design approach, Valmet DNAe offers an integrated, up-to-date system that streamlines IT/OT convergence, eliminating the need for separate OT data warehousing and helping companies reduce production costs and optimize operations.

Whether you're looking to streamline IT/OT convergence, improve cybersecurity, or future-proof your automation platform, we're here to help you tackle your specific challenges.

Text: Kelly Duval

Don’t miss out on the future of autonomous operations

Contact us to discover how Valmet DNAe and our cybersecurity services can support your digital transformation.

Contact usRelated articles