Winder dust control system enhances paper roll quality on Zhejiang Shanying PM 13

Mar 11, 2025

With technological advancements in printing technology, the market now demands increasingly high standards for paper quality, especially regarding the paper surface cleanliness. The dust levels on the paper surface have become one of the most important indicators affecting the paper quality. Zhejiang Shanying PM 13 was experiencing excessive dust on paper rolls and turned to Valmet for a reliable solution.

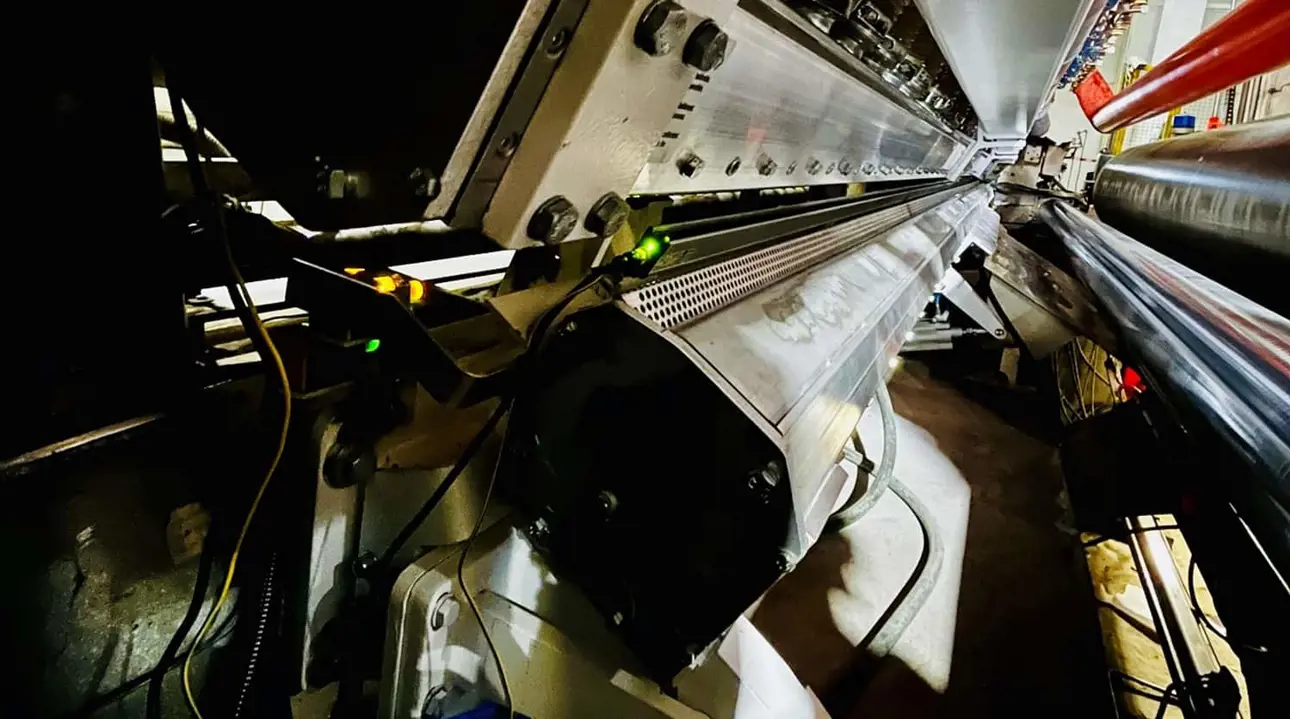

Zhejiang Shanying PM 13 started up in 2011 in China. It mainly produces White Top Liner with an annual output of 560,000 tonnes. PM 13 is a Valmet OptiConcept M high-speed paper machine with winders from another supplier. To improve the paper roll quality, Zhejiang Shanying wanted to optimize and transform the dust removal equipment of the winder. However, the original equipment could no longer meet the higher production requirements through simple retrofitting. After an on-site investigation, Valmet delivered a high-efficiency WCM OnSheet winder dust control system for PM 13.

Reliable delivery with excellent cooperation

"The rebuild was very successful, and the downtime was short," says Shen Qiang, the winder supervisor at Zhejiang Shanying, emphasizing the good cooperation with Valmet and his satisfaction. "Everything was well organized. There were no delays, and our cooperation was excellent.”

“The dust removal performance after the rebuild has been very good. The cleanliness of paper rolls from the winder has improved, increasing our customer satisfaction. The customer satisfaction is always the common goal with Valmet, and our cooperation has been a complete success,” says Jiang Yunhong, Manager of Zhejiang Shanying PM 13.

Advantages of WCM OnSheet winder dust control system:

- Air knife cleaning technology: it directly acts on the paper surface, significantly enhancing the paper cleanliness.

- Design without support rolls: it is highly adaptable to various types of winders.

- Dust control consists of a blowing nozzle and a suction nozzle and performs a good dust removal: it effectively collects and separates dust, maintaining a clean production environment.

- Airfoil geometric control: it precisely regulates the web surface, combined with balanced blowing and suction technology, for a more precise operation control.

- Ionization bar for static electricity and dust removal: it releases static electricity from the paper web and dust, enhancing cleaning effectiveness and ensuring a stable paper quality.

- Reliable performance: it perfectly integrates with the winding process, ensuring the stability of the entire system.

“Our solution is widely compatible with various winder models, with an easy installation and a significant reduction in the installation downtime. During the start-up phase, Valmet made sure that the dust removal system was integrated with the winding process. The winder lifecycle service fully meets the diverse needs of the customers,” says Shannon Yuan, Product Manager, Winder Section, China Services, Valmet.

Want to talk to our process ventilation experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our experts