Energy-saving retrofit project successfully completed at GOLD HONGYE PAPER (HUBEI) CO., LTD. in Xiaogan

Oct 23, 2024

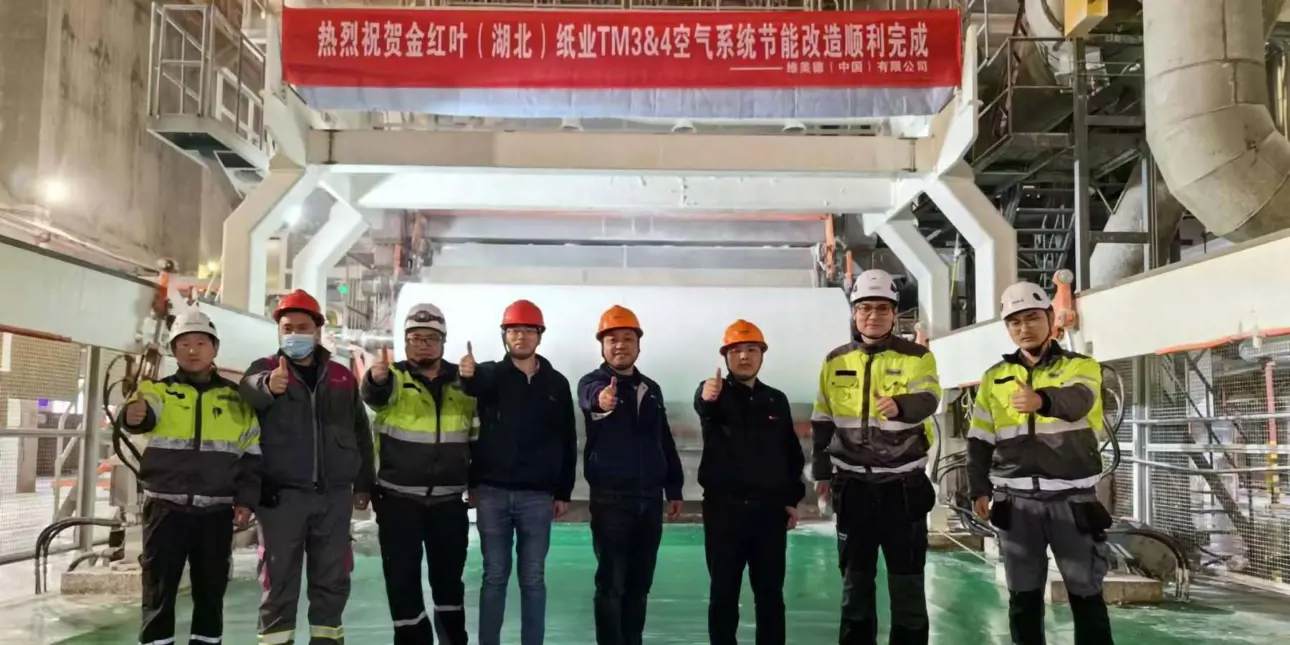

A close cooperation between GOLD HONGYE PAPER in Xiaogan and Valmet has generated good results. The TM 3 and 4 air system technology retrofit project has been successfully completed and started up. The TM 3 and 4 production lines of GHY Paper Hubei have been in service for over ten years, and its air system technology has not kept up with the latest upgrades. To enhance the company’s market competitiveness by reducing gas and electricity consumption, GHY Paper Hubei commissioned Valmet to carry out relevant modifications to its air system.

In this project, Valmet leveraged its extensive experience in air system energy saving to provide GHY Paper Hubei with comprehensive and efficient solution. This included optimizing and upgrading the air system process, supplying key equipment, and making detailed improvements and optimizations to the burner system. Valmet also took full responsibility for the on-site equipment installation, commissioning, and start-up services.

Reduction in gas and electricity consumption

Since the project started up, the retrofit has shown significant results. The gas consumption of the paper machine has been reduced by an average of 10 cubic meters per ton of paper, and electricity consumption has decreased by 40 kWh per ton of paper. Achieving significant energy-saving and emission reduction goals. This achievement is attributed to the adoption of Valmet’s latest air system design standards and the introduction of the Cascade series air system concept, making the entire system process more efficient and energy-saving. Additionally, the reconstruction of pipeline layout, the upgrade of the burner system, the re-selection of fans, and the application of high-efficiency gas-to-gas heat recovery towers have all contributed significantly to the improvement of system performance.

Since the project started up, the retrofit has shown significant results. The gas consumption of the paper machine has been reduced by an average of 10 cubic meters per ton of paper, and electricity consumption has decreased by 40 kWh per ton of paper."

A successful collaboration and start-up

“This time, we chose Valmet for the air system energy-saving retrofit because we believe in Valmet’s professional capabilities. With the technical support of the APP Group GT’s R&D team and Valmet’s expert team, we discussed and formulated a globally pioneering technical solution." says Dai Peng, Deputy General Manager, Golden Leaf (Hubei) Paper Co., Ltd. Dai Peng continous

The project was very successful from planning to on-site execution. After the retrofit, the operation is good, especially the reduction in gas and electricity consumption, which we are very satisfied with. We also highly value the safety upgrades of the gas system. We appreciate the efforts of both parties.” Dai Peng, Deputy General Manager, Golden Leaf (Hubei) Paper Co., Ltd.

Xiang Lirong, Senior Manager of Tissue Service, Valmet China explains; “C&S Paper is a long-term partner of Valmet. In this project, the customer’s gas and electricity consumption reduction effects are significant, and the operational performance has also been improved. Valmet has always been at the forefront of technology in the economic operation of air systems, and we can help customers achieve energy recovery and consumption reduction goals.”