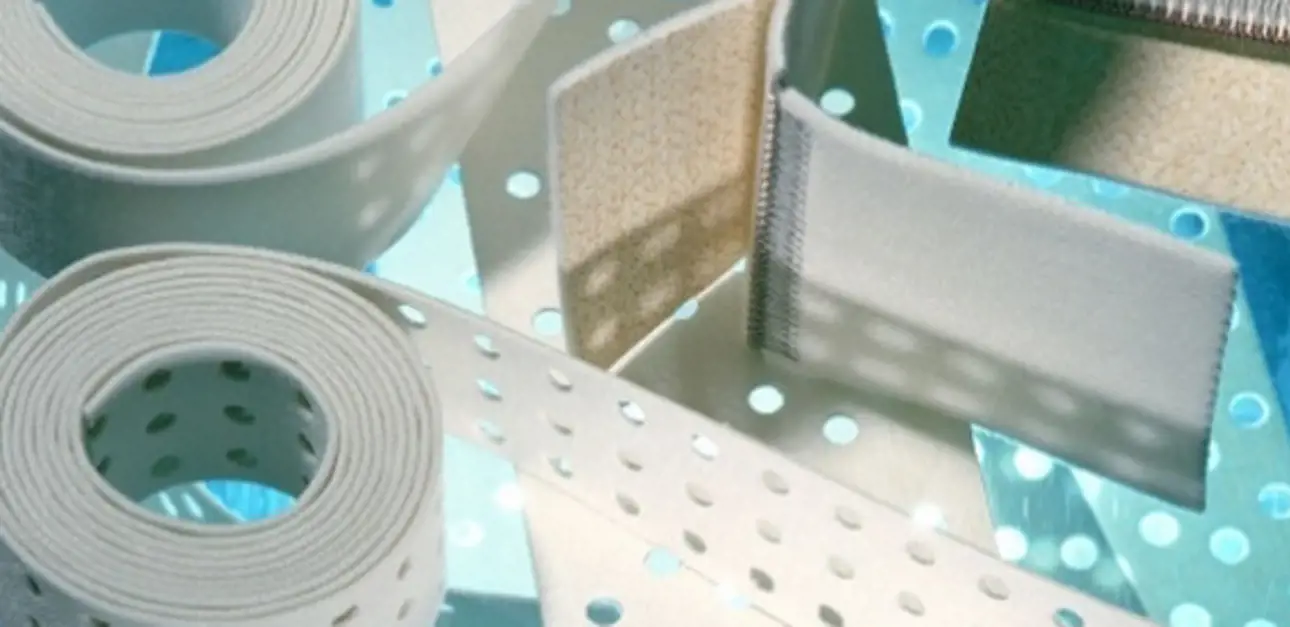

Feed belts and perforated feed belts

For the feeding of the linen into the ironer we produce a special compact 100% polyester needled felt with special finishing and heat setting. The belts can also be perforated for the vacuum feeder. Our ironing belts have a very smooth surface, which gives a non-marking finishing to the linen. We provide also covers for tracking and pressure roll.

Our feed belt/ribbon of synthetic compacted needled felt made of 100% white compact polyester with heavy duty multifilament scrim equips most of the ironers made today in the world and definitively substitutes the traditional cotton feed belt.

Advantages:

- Perfect dimensional stability (no elongation and no shrinkage) because of its heavy duty multifilament internal scrim;

- No fraying like the cotton belt (ribbon) and no need to glue or patch each end before hooking;

- Both edges are melted to avoid threads hanging from the side of the belt;

- The side in contact with the ironer driving roll has a rough surface to increase the grip of the belt.

This synthetic fiber product with the above advantages provides a much longer working life than the traditional cotton belt (ribbon).

Extreme grip belts

The compact silicone gives the belt more adherence than any other kind of material. The silicone used is 100% silicone of 1st quality with specific non-toxic properties as the one used for the food industry. As the belt has a 100% synthetic felt support, the siliconized belt will have a longer working life on the laundry machines.

The 100% synthetic needled felt belt with non-slippery siliconized side may be delivered in different forms depending on the specific applications:

1) For feeder belts

Ref. Valmet Grip TSC (77/20.135.B1.3.TC1M.SC) (earlier known as FANAGRIP TSC)

Ref. Valmet Grip TSC-H (77/25.150.2.TC1M.SC) (earlier known as FANAGRIP TSC-H)

With or without holes.

Advantages:

- Due to the excellent power of the adherence of the belt, the linen is fed perfectly stretched

- Version TSC-H:

- Heavier – more stability

- Thicker – more straight (less curving) over the width

- Thicker – no reinforcement needed under the hooks

The belt is also excellent to be used on the folders, stackers and transporters of linen to substitute cotton belts with or without rubber, elastomer, PVC belt, etc.

2) For folder belts, stackers and transporters of linen

To substitute the cotton belts with or without rubber, elastomer, PVC belt, etc.

Advantages:

- Much better transport of the linen in the folders providing a more perfect folding of the linen specially in the cross folder section.

- Much larger dimensional stability: due to the property of the silicone, this silicone belt will stretche less than the cotton belts (for this reason it is eventually necessary to revise the dimensions of the belts with silicone)

- The working life is longer: Valmet’s 100% synthetic needled felt belt with non-slippery siliconized side will not fray like a traditional woven cotton belt.

- Less static electricity: due to its insulating properties, the siliconized belt has an excellent behavior regarding the negative problems of the static electricity.

3) For tracking roll padding

Ref. Valmet Grip AD (77/20.135.B1.3.TC1M.SC.AD) (earlier known as FANAGRIP AD)

The tracking roll of the feed belts is padded in spiral with the adhesive non-slippery siliconized belt.

Advantages:

- Due to the non-slippery power, all the feeding belts will be pulled in a more perfect and uniform way. This is especially true on the center of the ironer where the belts use to slip, because of the potential curve of the tracking roll. The feeding of the linen into the ironer will be more perfect and correct.

- The working lifetime is more than 5 times compared to the traditional grip synthetic rubber belt, as the rubber belt crystalizes and loses its adherence quite quickly.

Perforated feed belts

Our perforated feed belts of special compact 100% polyester needled felt with special finishing and heat setting; one hard side for better grip and both edges are melted to avoid any threads hanging.

Mostly used for vacuum feeder. Also available on the extreme grip belt.

We produce the main hole patterns for Jensen, Biko, Weir, Amko, Olma, Vega Systems, Lapauw, Kannegiesser, Toto, Laco, Electrolux, Lavatec, Girbau, Girbau Robotics, Chicago Dryer, etc.

Supplied in rolls of +/- 50 m of desired width o