Mechanical textile recycling processes

Our fiber treatment technologies for mechanical recycling processes handle raw materials to transform them into a fiber form that is fit for purpose in subsequent chemical processes. The characteristics of the raw material define the starting point of the treatment process, ensuring that the fibers are optimally prepared for the next stages of production.

Innovative solutions for sustainable textile fiber recycling - From material intake to final processing

Textile receiving, sorting, and storage

Efficient handling of incoming textile materials is the first step in mechanical recycling. Textiles can arrive in bales, bulk, or large sacks, often wrapped in plastic or tied with metallic or synthetic strings. A robust system of conveyors, metal removal, and de-wiring ensures smooth processing while maintaining safety and efficiency.

Valmet Solutions:

Conveyors - Customizable for handling varying forms of raw textiles.

Metal Removal - Protect downstream equipment with effective metal separation systems.

De-wiring Units - Streamline the process of removing binding materials, preparing bales for further processing.

Shredding and tearing

Shredding and tearing reduce textiles to a size suitable for downstream processes, minimizing dust and fine particles for energy-efficient operations. Uniform size reduction ensures better performance in subsequent refining or chemical treatments.

Why Valmet?

Our innovative design reduces dust generation, maintains energy efficiency, and supports optimal textile processing needs, no matter the requirements.

Fiber treatment and refining

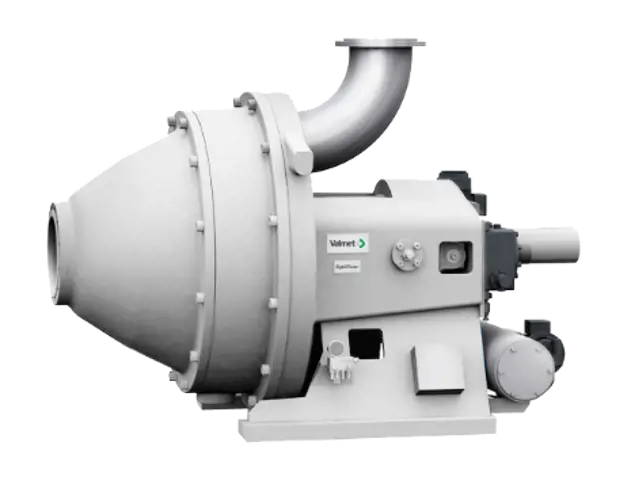

Valmet’s refiners, including the Valmet Conical Refiner Conflo, Valmet Conical Refiner Pro and Valmet Disk Refiner (DD) refiners, are optimized to handle textile fibers with high efficiency. These solutions are engineered to enhance fiber properties for further applications.

Suitable for various materials

Cotton: Valmet Conical Refiner Conflo is the world’s top choice for cotton fiber refining, successfully adapted also for other long-fiber materials.

Non-Wood Fibers: Valmet’s fiber refining technologies extend to non-wood fibers such as hemp and agro-residues. These materials benefit from our ability to optimize refining for unique properties, supporting innovative recycling and processing applications.

Key Features

Customization: Tailored to the needs of diverse fibers—whether for mechanical or chemical downstream processes.

Strong in-house filling development: Valmet's refiners feature cutting-edge fillings that reduce energy consumption and maximize fiber qualities.

Automation with FS5 and MapQ: Automation enables precision control of fiber quality and properties. Valmet’s FS5 standalone fiber property measurement device and MapQ online monitoring system help ensure consistent results in fiber refining.

Impurity removal of heavy and light weight particles

Effective cleaning and screening are crucial for ensuring the highest levels of pulp purity, supporting optimal performance in subsequent processing steps and delivering superior end-product quality.

Valmet is a leading supplier of advanced cleaning solutions designed to tackle all types of impurities in textile pulp. Our extensive portfolio includes cleaners optimized for both high-consistency and low-consistency operations, ensuring efficient removal of contaminants regardless of their size or weight.

Following the cleaning process, barrier screening technology is applied to textile pulp to remove impurities or fiber flocks based on size, ensuring a uniform pulp quality for further processing.

Dewatering

Removing water and increasing consistency is essential in textile recycling. Valmet’s dewatering technologies include:

- Disc Filters: Efficient for large-scale dewatering.

- Screw Presses and Twinroll Presses: Ideal for high-performance dewatering after chemical processes.

Reject handling

Textile recycling generates various reject streams that require customized solutions. Valmet’s expertise in reject handling, drawn from recycled fiber/OCC processes, ensures tailored solutions that maximize efficiency and minimize waste.

Features:

- Compact system design

- Expertise in processing metal, sand, and fiber rejects

- Fit-for-purpose technologies to suit specific process requirements

Contact us to explore how we can support your success with textile recycling

Stay ahead in the dynamic textile market with innovative concepts designed to enhance fiber production. We can offer flexible approaches tailored to your needs.

Contact us