Air emission control services for pulp production

Valmet’s service offering is designed to match your specific needs, whether it's enhancing plant availability, environmental performance, or both. Depending on your requirements, the service solution can be provided as a one-time delivery or as a longer-term partnership through service agreements. By working together, we can ensure maximized reliability and optimized performance of the production process.

High availability and supply reliability

Optimized and predictable operation cost

Sustainable operation by regulations

Increased equipment lifetime

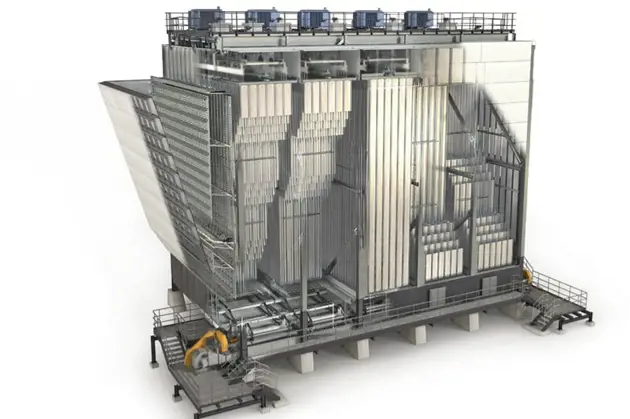

Improved capacity and equipment lifetime for electrostatic precipitators (ESP)

With the right service, we can increase equipment lifetime, and improve capacity and equipment availability. Whether you are looking to improve efficiency and reliability, or you want professional help for your shutdown management to minimize operational downtime, we have you covered. If you are looking to modernize your equipment, we offer refurbishments and upgrades to improve performance and adapt to new operational requirements. Our services are available for all ESP designs including other OEM equipment.

Read more about our services for electrostatic precipitators

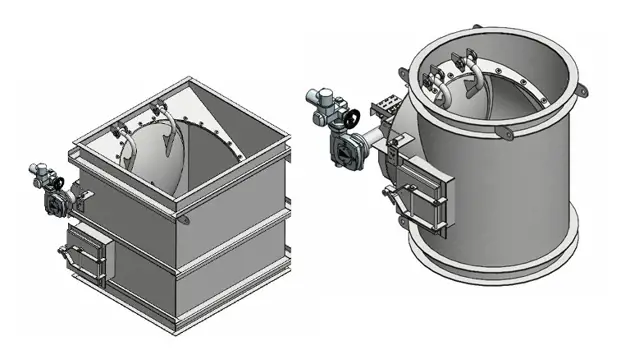

Flue gas disc dampers - cost-efficient and proven design

Our flue gas disc dampers serve as the primary solution for recovery boiler and lime kiln installations. With a proven design ensuring excellent sealing properties, they offer a cost-efficient solution for the equipment which needs to be isolated. Our service includes inspection, maintenance, and provision of spares.

These dampers are a cost-efficient choice for ON/OFF usage at the inlet and outlet of equipment that requires isolation. Available in circular or rectangular designs and various sizes and materials, they can be tailored to different needs.

Increased equipment lifetime for Wet Electrostatic Precipitators (WESP)

We offer services to maintain your performance, including efficiency, pressure drop, and electricity power consumption, at target levels. Additionally, these services contribute to an extended equipment lifetime. The service scope includes:

- Mechanical inspections during shutdowns

- Electrical inspections during operation

- Troubleshooting, site audits, and process studies

- Installation of new electrodes and transformers

- Replacement of nozzles and washing pipes for the scrubber section

- Maintenance of auxiliaries such as backflush filters, flotation units, and rotary drum screens

- Honeycomb repairs and larger refurbishments

- Internal cleaning of accumulated deposits in WESP

Questions about equipment maintenance or support for equipment or process performance development?

Whether it’s a single process survey, equipment maintenance, shutdown management or full maintenance, don’t hesitate to contact your closest Valmet Service Center for guidance.

Contact us

Flue gas scrubber service to meet performance targets

The flue gas scrubber service will extend the lifetime of your equipment and help you achieve performance targets such as efficiency, pressure drop, and power consumption. The service scope includes:

- Inspection of scrubber internals

- Troubleshooting, site audits, and process studies

- Maintenance and exchange of internal parts

- Renewal of washing pipes

- Repairs and modifications to flue gas inlet channels

- Maintenance of auxiliaries, such as water treatment and additive dosing systems

- Retrofits/Modernizations to maintain equipment reliability or align equipment with changed capacity or fuels

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}