Valmet Wet End

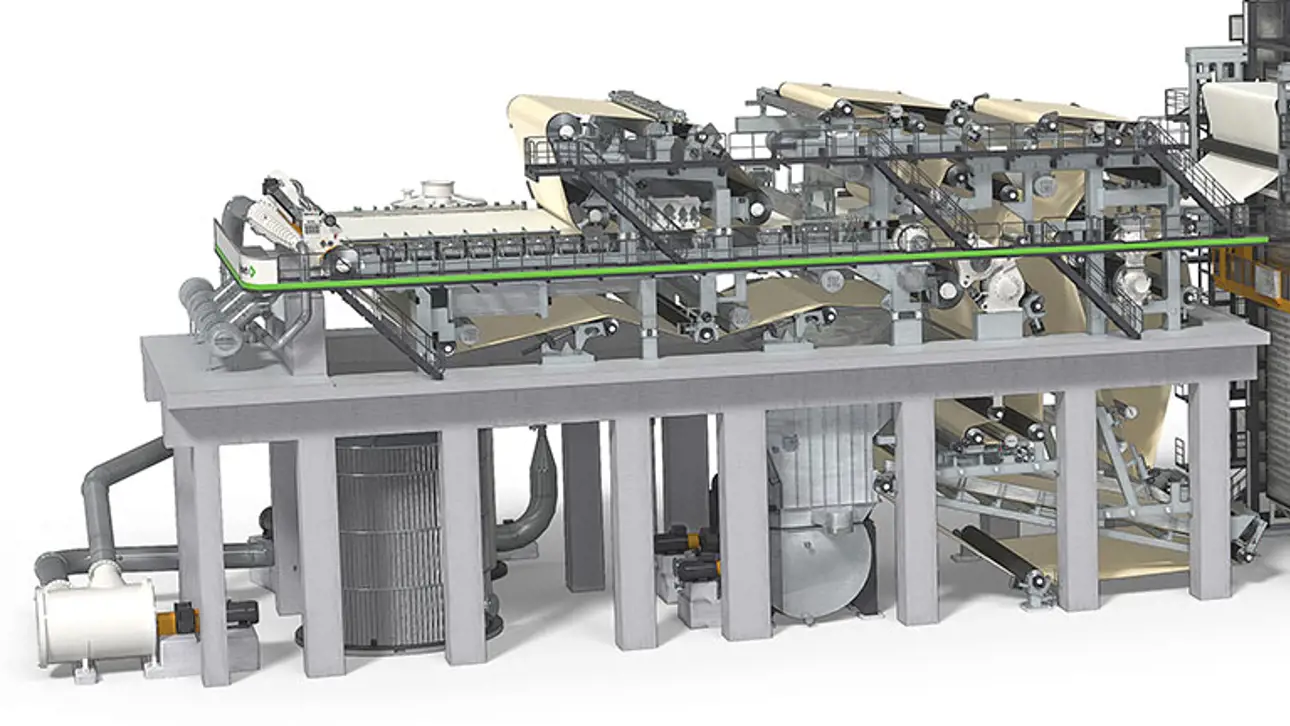

Valmet offers several alternative wet end set ups. All alternatives consists of a headbox where excellent web profile is ensured, a forming section where the pulp is dewatered and a pulp web is formed, and a press section where a combination of presses increase the web dryness. By avoiding open draws few web breaks and more production hours are assured. An automatic tail threading device takes the tail to the dryer and secures fast and safe tail threading at high speeds.

Excellent web profile and good formation

The modern Wet end features an advanced dilution-controlled hydraulic headbox, which ensures and excellent web profile both in cross and machine directions.

Effective dewatering and few web breaks

By minor open draws, fewer web breaks and more production hours are assured.

High dryness and low steam consumption

With two Shoe presses, the wet end can deliver very high dryness values and savings in steam costs for any kind of pulp.

Reliable and optimal operation

A sophisticated automation and control system, covering process, machine, drive, and quality controls, as well as condition monitoring and baling management ensures the best performance.

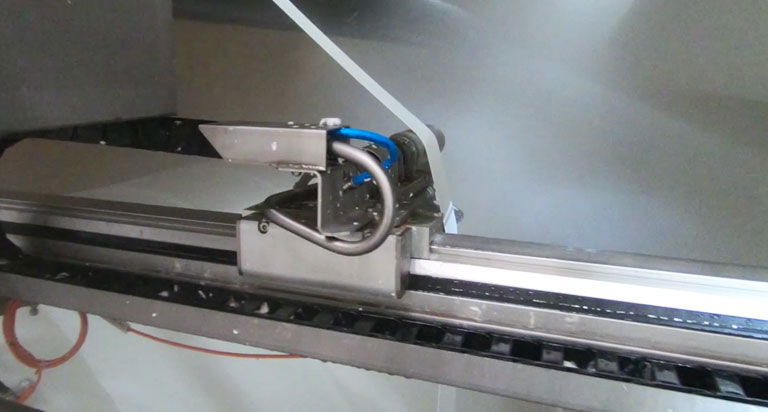

Automatic tail threading increases production

Reliable and simple tail threading is a key to achieving high production efficiency. Problems with manual tail threading are often the main reason it takes an unnecessarily long time to get production back up after a stop.

Tail threading robots can be installed on most machines and makes operation safe. There will also be less variance between different shifts. The motorized tail threading system is installed in three different positions to allow the start-up of the machine without the need of using hands. The time to get back up to full production speed is no longer limited by the manual tail threading. Instead of slowly ramping up the speed, high production can be reached almost immediately.

Pilot trials - The proving grounds for improved efficiency

Valmet provides the world’s most comprehensive offering of testing and piloting services for pulp, board and papermakers worldwide. The pulp drying process is covered, from screening to pulp sheet cutting and the pilot facilities are equipped with online video monitoring systems, making trials available also remotely – no matter, where you are located. The pilot plant facilities house up-to-date laboratories that feature comprehensive range of testing instruments and equipment. They provide an ideal environment for thoroughly analyzing the pulp drying on the pilot machines.

Our solutions

Our expertise is at your service

We at Valmet are committed to moving our customers performance forward and ensure smooth, disruption-free operation, supporting you all the way.

Contact us