Field services for cooking and fiberline equipment

Higher pulp yield, reach targets for availability and decreased kappa variations connected to process parameters

Ensure overall equipment efficiency is maintained for fiberline equipment with our inspection services together with process audit we can ensure process related targets are meet. Our Field Services includes fast on-call equipment services, shutdown management, support, and recommendations on-site or remotely.

Decreased kappa variations

Higher pulp yield

Chemical savings

Optimizes spare-part requirements

Audits to understand equipment status

Customer challenge can many times be connected to both availability of equipment in feedline together with pulp yield and pulp quality related challenges.

Valmet field service support customer to meet targets related to understanding equipment status planning needed activities, recommendations on actions needed to reach targets set for maintenance and performance cost. Valmet services can include mechanical audit, process audit and preferable a combination of both to link that overall performance parameters together.

A perfect shutdown service

A perfect shutdown involves cost-efficient performance, holding time schedules and developing mill staff competence. Our capability and experience of putting a project into effect properly is the key to a perfect shutdown – the essence of our Pulp to Pulp concept.

Performance monitoring for twin roll presses

Process evaluation is done via Valmet Performance Center where Valmet expertise are available. On the customer specific dashboard Valmet experts and operators can easily track and follow performance of the press.

- Lower operating cost due to less chemical consumption and fewer unplanned stops

- Improved performance of wash press operation together with predicting and supporting maintenance planning

- More efficient spare parts planning

Find out more about Valmet Performance Monitoring for TwinRoll press

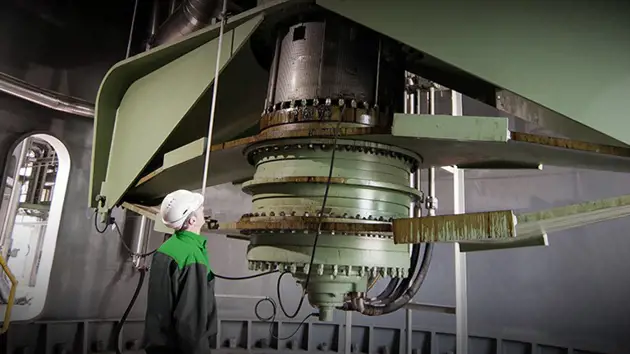

Secure product quality and availability of your top separator

With our top separator services we guarantee the best performance possible, secure product quality, availability & lifetime of the equipment.

- Increases availability

- Reduces maintenance cost

- Improves the process

- Securing correct operation of machinery

Find out more about Valmet Top Separator Services

Questions about equipment maintenance or support for equipment or process performance development?

Whether it’s a single process survey, equipment maintenance, shutdown management or full maintenance, don’t hesitate to contact your closest Valmet Service Center for guidance.

Contact us

Get the maintenance costs down by regular outlet device overhaul services

Making an outlet device overhaul service will secure the product quality, availability, and maintenance cost.

• Lower maintenance cost

• Secure runnability

• Increases availability

• Securing correct operation of machinery

Find out more about Valmet Digester Outlet Device Services

Good diffuser performance begins with the hydraulic system

Hydraulic measurement of the system is an important tool to gain information for preventative maintenance, overhauls or future rebuilds of the system.

• Minimized risk for breakdowns

• Lower maintenance cost

• Process improvements

• Improves and maximize life length of equipment

Find out more about Valmet Diffuser Hydraulic System Audit

Process and mechanical inspection of twin roll press to increase productivity

Our inspections services involves a process and mechanical inspection of the twin roll press. When the audit is completed the customer receives a detailed report containing recommendations for mechanical and process changes, spare part inventory as well as machine documentation.

• Fewer unplanned stops

• Increased accessibility

• Better pulp quality

• Higher productivity

• Proper machine documentation

• Right spare parts in stock - Less capital tied-up

Find out more about Valmet TwinRoll Press Inspections

Do you need equipment maintenance or support for equipment or process performance development?

This handbook gives you guidance in best practices for keeping your operation in good condition and with service interval recommendations helping you prevent unexpected failures.

Download for freekeyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}