Refiner Segments - Pro safe for pulp production

Lighter, safer way to move your refining performance forward

Taking steps to optimize low consistency refining helps pulp mills achieve their performance and production goals. While specific refining goals may vary from mill to mill, refiner segment pattern and design can have a substantial impact on refining efficiency.

Lighter and safer

- 75% lighter than traditional cast refiner segments

Reduce energy consumption

Improved fiber quality

Minimized equipment downtime

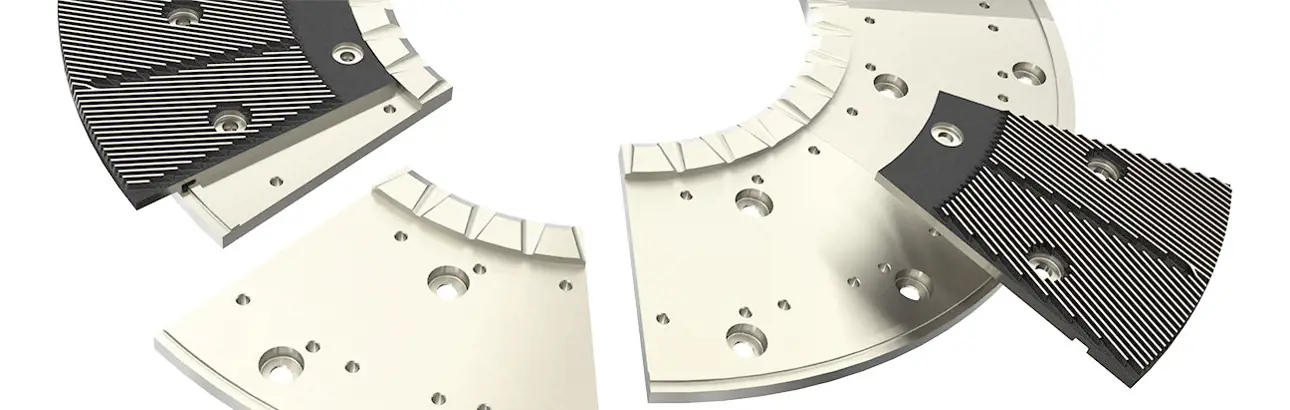

Valmet Refiner Segments - Pro safe are the lighter, safer alternatives to traditional plates. First introduced by legacy manufacturer J&L Fiber Services, Valmet is now the OEM for Pro safe refiner segments, producing them out of its Waukesha Service Center, in Waukesha, WI.

More patterns, optimum design and performance

The unique casting process used on Valmet Refiner Segments - Pro safe enables production of overhung designs that are built to drive performance. This means increased refining capacity at lower intensity with longer plate life. When compared to traditional refiner segments, Valmet customers using Valmet Refiner Segments - Pro safe benefit from:

- Higher capacity

- Lower refining intensity

- Longer plate life

- Plug-resistant plate patterns

Pattern designs

Valmet Refiner Segments - Pro safe can be fabricated in any of Valmet’s signature pattern designs.

- Alternating Deep Groove (previously known in the industry as ProMax ReverseFlare)

- Reverse flare groove (previously known in the industry as ReverseFlare)

- Constant Angle Multi-Zone

- Constant Angle

- Ultra low intensity

- Parallel Bar

- Variable groove

- Milled Bar

Case study: Replacement refiner segments improve safety and efficiency at North America mill

How do you maximize low consistency refining efficiency while also improving operator safety?

Read and download the casePlate holder offering for Valmet Refiner Segments – Pro safe

|

Refiner |

J&L plate and holder series |

Plate holder mounting diameter |

Plate holder segment Weight |

Pro safe max. refining diameter |

Pro safe segment weight |

Standard segment weight |

|

DD3000 |

42EJPH |

1067 mm (42”) |

9.1 kg (20 lbs) |

1118 mm (44”) |

4.5-5.4 kg (10-12 lbs) |

16.3-20.4kg (36-45 lbs) |

|

DD4000 |

42EJPH |

1067 mm (42”) |

9.1 kg (20 lbs) |

1168 mm (46”) |

4.5-5.8 kg (10-13 lbs) |

16.3-20.4kg (36-45 lbs) |

|

46EJPH |

1168 mm (46”) |

13.6 kg (30 lbs) |

1219 mm (48”) |

4.5-6.8 kg (10-15 lbs) |

20.4-22.7 kg (45-50 lbs) |

|

|

DD4500 |

42EJPH |

1067 mm (42”) |

9.1 kg (20 lbs) |

1168 mm (46”) |

4.5-5.9 kg (10-13 lbs) |

16.3-20.4kg (36-45 lbs) |

|

46EJPH |

1168 mm (46”) |

13.6 kg (30 lbs) |

1219 mm (48”) |

4.5-6.8 kg (10-15 lbs) |

20.4-22.7 kg (45-50 lbs) |

|

|

DD6000 |

42EJPH |

1067 mm (42”) |

9.1 kg (20 lbs) |

1168 mm (46”) |

4.5-5.9 kg (10-13 lbs) |

16.3-20.4kg (36-45 lbs) |

|

46EJPH |

1168 mm (46”) |

13.6 kg (30 lbs) |

1219 mm (48”) |

4.5-6.8 kg (10-15 lbs) |

20.4-22.7 kg (45-50 lbs) |

|

|

TwinFlo |

42TFPH |

1067 mm (42”) |

9.1 kg (20 lbs) |

1194 mm (47”) |

4.5-6.4 kg (10-14 lbs) |

11.3-15.9 kg (25-35 lbs) |

Pro safe segments are designed to fit Valmet’s customized, long-life plate holders with overhung and underhung capabilities.

Questions about refiner segments?

Contact our co-drivers and take full advantage of our innovations, patents and best practices. With the combination of parts and expertise, we can together make a difference at every stage of your production process. We have increased production output and decreased total costs together by applying optimal process parts to each position.

Contact usRelated links

Related articles