Debarking

Best possible cleanliness and economy with Valmet's debarking system

Valmet offers several debarking systems to cover the various needs depending on climate and different wood species. All debarking systems combine high capacity with easy and reliable operation and provide optimal bark removal with minimum wood loss. The design ensures effective bark separation from the logs prior to the chipping process. Many wood species coming from forest plantations are difficult to debark, compared to easy-to-debark softwood which was the primary raw material only a couple of decades ago. For example, eucalyptus bark emerges in long strips and mainly follows the logs out of the debarking drum. For this reason, a special bark separation system after the drum is necessary.

High capacity

Easy and reliable operation

Optimal bark removal with minimal wood loss

Effective bark separation from logs

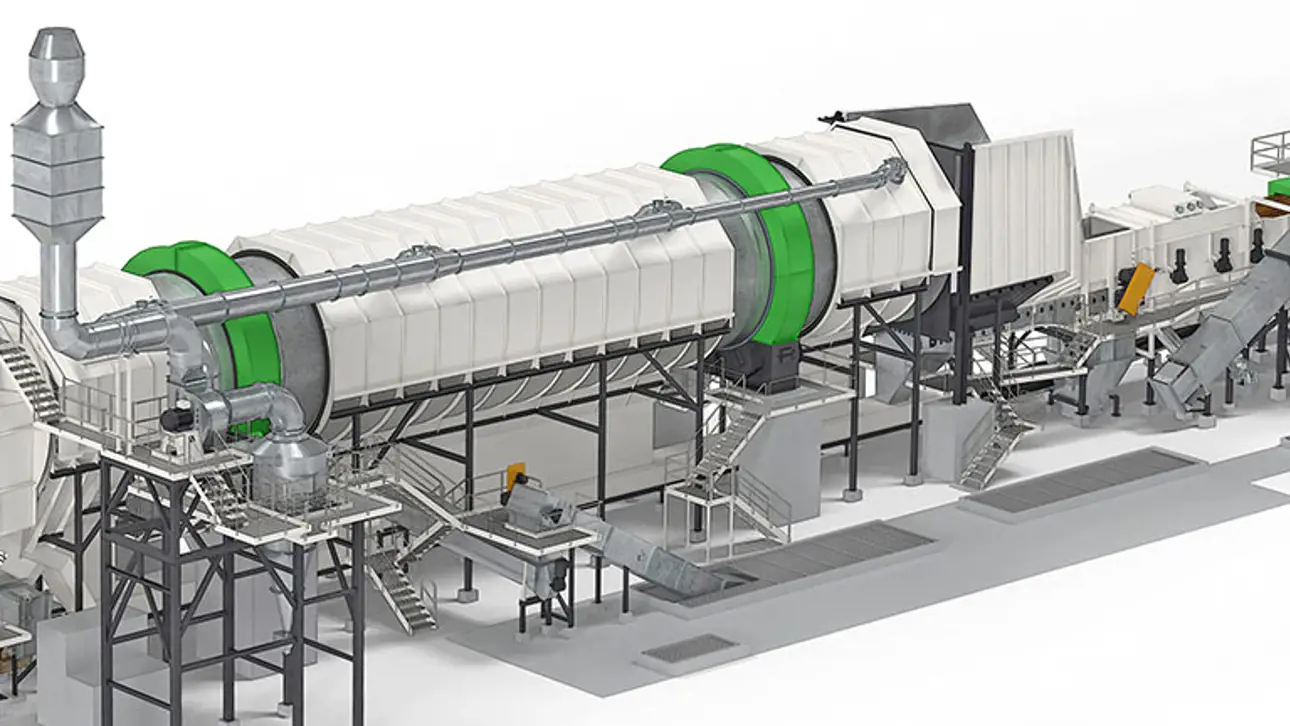

Debarking drum with rubber tyre support

Valmet's rubber tire-supported barking drum features an ideal support and drive system using heavy-duty standard rubber tires. This enables remarkably easy maintenance, which is as easy as changing the tires on a truck. The drum can be transported in pieces, which makes on-site assembly possible. The support design enables the use of the existing foundation when replacing any kind of barking drum. Optimized tire loads and location ensure a long service life and effective utilization of the drum shell. The elasticity of the rubber tires minimizes vibration and shock loads against the foundation and the drum shell.

Debarking drum with hydrostatical support

When choosing Valmet's hydrostatically supported barking drum, high reliability of the drum is guaranteed by hydrostatic support bearings, enabling high static and dynamic loads. Thanks to an ingenious supporting system with an oil film between the support ring and the bearing shoes there is no mechanical contact and no wear in the supporting system. The large drum size enables high capacity debarking in a single line. This feature minimizes total investment cost.

Valmet Roller Debarker

Valmet Roller Debarker combines high capacity, excellent debarking performance and robust design. This mechanical debarking system effectively handles challenging logs, including frozen ones, as well as those with stringy bark, smaller diameters, or crooked shapes, making it ideal for various wood species, such as eucalyptus, pine, and acacia.

It ensures a smooth debarking process, utilizing rotating debarking rolls that lift the logs inside the drum. Friction between logs and mechanical teeth work together to remove the bark efficiently. This results in high debarking quality is with minimal wood loss and a low level of residual bark.

The debarking process, resulting in logs of the best possible cleanliness, is essential for any pulp, paper and fiberboard mill. The raw material is a major expenditure and therefore, the way the logs are debarked is important for the total economy of a mill.

Our expertise is at your service

We at Valmet are committed to moving our customers performance forward and ensure smooth, disruption-free operation, supporting you all the way.

Contact us