Industrial Internet solutions for tissue

Let’s have a dialogue with data to improve the performance of your mill! Valmet Industrial Internet (VII) offering covers an extensive range of solutions and applications for Tissue.

ServicesFilters

Industrial Internet solutions for tissue

Let’s have a dialogue with data to improve the performance of your mill! Valmet Industrial Internet (VII) offering covers an extensive range of solutions and applications for Tissue.

Services

New Technology

How to maintain the competitiveness of your core processes and to develop them throughout the lifecycle? We provide a wide range of solutions for upgrading and enhancing processes and machinery. The scope is always based on your specific needs and the solutions are tailored to maximize the performance of the processes. This can be a cost-effective way to improve capacity, reduce emissions or extend the lifetime of your equipment. As a leading technology expert in energy, we have extensive expertise and experience. This knowledge is incorporated in all our products, giving us exceptional insight into all aspects of upgrading processes and equipment.

Services

Robotic Inspection Services

View and track potential defects in capital equipment from up to thirty feet away with Valmet Robotic Inspection Services.

Services

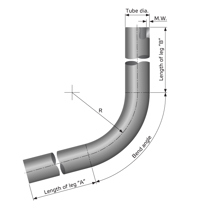

Valmet Gang Bend Tubing

Services

Learning Services

Why do companies with similar technology generate different results? Why do people with the same task vary in performance? The difference can be knowledge.

Services

Service agreements for pulp production

Helping you to meet and exceed your pulp mills targets is the key driver in our everyday work. The best results are made when working together through the lifecycle of your pulp production line - equipment, machines and processes. Whether it’s about planning, start-up or operational phase we are able to offer you the right combination of services for every stage in the lifecycle, ensuring maximized reliability and optimized performance, allowing you to focus on your core business.

Services

Alumina industries

Whether your filtration challenges are in Green Liquor, Red-Mud Residue, Seed or Hydrate or even Dedusting, Valmet has an optimized filtration solution for you. Valmet Alumina Process Filtration Fabrics are developed for efficient process filtration in demanding conditions, always striving to deliver measurable added value to your operations. Our tailor-made fabrics offer high performance in both Wet Process and Gas Filtration/Fume Treatment across the alumina refining and aluminium smelting production cycles.

Services

Tailings filtration

Today, many mining companies have switched the traditional way of handling mine tailings – storing the mixture of mining residue and water in ponds – to dry stacking. In dry stacking, the tailings go through a filtration process leaving them in a dense and stable form. An essential part of the filtration process are filter fabrics. Valmet’s filter fabrics are always tailor-made for the customer’s equipment and process. They ensure production reliability and create savings on energy, water and maintenance costs.

Services

Extended reality learning

Valmet Extended Reality is a multipurpose mixed reality platform, streamlining the design review, training, preplanning maintenance and remote collaboration processes for different industries.

Services

Maintenance master data

Master data is a solution for managing maintenance operations at your pulp, paper and tissue plants. Whether you are using CMMS (Computerized Maintenance Management System) or EAM (Enterprise Asset Management) Valmet can help you to collect data to improve efficiency.

Services