Improve the tissue drying process with solid technology

Advantage AirCap

Invest in solid technology that grants quality tissue, optimum drying and energy saving. Explore the Valmet Advantage™ AirCap™.

Optimizes drying and energy efficiency

Improves the work environment in terms of safety and maintenance

Choice of solutions to decrease emission levels

Proven technology to meet today´s challenging market

When investments are strongly driven by the need to be more competitive, improve product quality, while being environmentally responsible, Valmet Advantage AirCap (AAC) is the answer. We offer you our 50-year experience with more than 500 Yankee hoods successfully delivered worldwide, as well as our continuous research and product development.

Designed to optimize drying and energy efficiency

The construction of the Advantage AirCap is well proven to optimize the distance between the hood and cylinder on the AirCap wrap at all operating temperatures. A controlled thermal expansion also ensures a long life cycle of the equipment, one of the longest in the industry. You can also choose a special construction that allows for operating temperatures up to 700°C.

The graph shows the correlation between gas consumption trend and hood/cylinder distance.

Reduces emissions and optimizes energy efficiency

The Advantage AirCap Air system is dimensioned and designed to optimize energy efficiency and reduce emissions to the atmosphere. Natural gas, LPG, steam, diesel oil, dual fuel burners, as well as steam and diathermic oil heated systems are supported. In addition, electric heaters can serve as an alternative to fossile fuels

For the best utilisation of exhaust air energy there is a heat recovery system for steam generation, combustion and make-up air, room ventilation, fresh and process water There is also a possibility to utilise co-generation (CHP) exhaust gases.

Effective moisture profile regulation

On the Advantage Aircap you have a full profiling on the Wet End and additional profiling zones on the Dry End edges to control over- drying. You also have a manual or actuator-remote controlled profiling zones.

Advantage AirCap Pro

The continued advancement of the Advantage AirCap technology has led to the development of an innovative system for addressing moisture profiling issues in greater depth.

The Advantage AirCap Pro moisture profiling system precisely adjusts temperature and drying intensity in areas where the paper is wetter than average. Conversely, the system reduces both temperature and drying intensity where the paper is drier than average, resulting in a more uniform moisture profile at the reel.

Patented and internationally recognized by Valmet, the Advantage AirCap Pro offers numerous benefits:

- Advanced paper profiling with superior performance: doubling the efficiency of conventional hoods by adjusting both air temperature and speed. The AirCap Pro can achieve higher drying temperatures where needed, surpassing the capabilities of conventional hoods

- Seamless integration: easily integrates into existing tissue machines, delivering remarkable peak-to-peak performance

- Energy efficiency: it minimizes electrical energy loss through the profiling dampers and reduces burner gas consumption by lowering the average air temperature used for drying

The new design determines remarkable benefits especially in case of very wet edges or where moisture profile is inclined.

Electric heaters and hydrogen burners for heating up the Yankee hood

At Valmet, we understand the importance of efficient and sustainable heating solutions in the tissue paper industry. Our electric heaters are designed to deliver superior performance, energy efficiency, and environmental benefits.

By utilizing hydrogen burners for heating up the Yankee Hood, tissue paper manufacturers can experience improved efficiency, reduced environmental impact, and cost savings

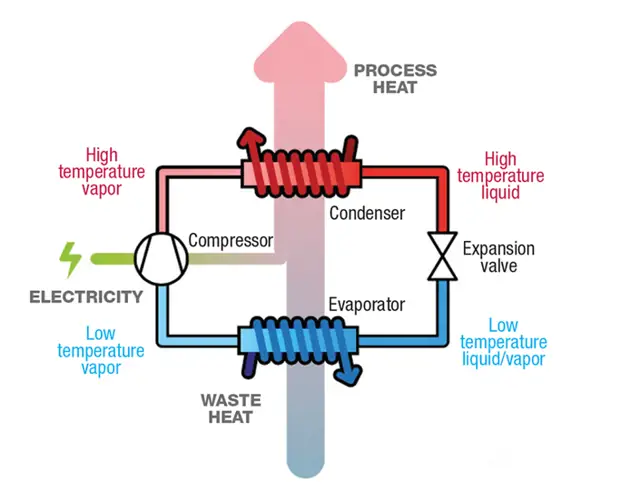

Integration of high temperature heat pumps in tissue mills

The drying section can be further optimized by utilizing the remaining energy in the exhaust. Even lower temperature exhaust with high humidity content can be efficiently used through the application of a High Temperature Heat Pump. Their technology is rapidly advancing, offering significant saving potential.

The integration with the paper-making process can be implemented in existing mills and brings multiple benefits:

- Improved energy efficiency thanks to the higher amount of heat recovered from the hood exhaust

- Reduction of water consumption

- Substantial reduction of CO2 emissions

- Ability to cover the entire thermal energy needs of a double-width machine

- Savings in carbon tax associated with emissions from fossil fuel boilers

A tailor-made solution can be designed to maximize the Coefficient of Performance based on the Steam and Condensate system design.

We can help you achieve efficient heating performance, energy savings, and operational excellence in tissue production.

Contact usQ&A about electrical heaters and hydrogen burners

Q: What are the advantages of using electrical heaters for heating up the Yankee Hood in tissue paper making?

A: The advantages of using electrical heaters for heating up the Yankee Hood in tissue paper making include precise temperature control, uniform heating, and reduced environmental impact compared to traditional fossil fuel burners.

Q: What are the benefits of using hydrogen burners for heating up the Yankee Hood in tissue paper making?

A: The benefits of using hydrogen burners for heating up the Yankee Hood in tissue paper making include clean combustion, minimal emissions, and environmental sustainability compared to conventional fossil fuel burners.

Q: What are the environmental benefits of using electrical heaters?

A: The environmental benefits of using electrical heaters include lower emissions, reduced pollution, and a smaller carbon footprint compared to traditional fossil fuel heating methods.

Q: Can I reduce carbon emissions with hydrogen burners?

A: Yes, hydrogen burners can significantly reduce carbon emissions compared to traditional fossil fuel burners because hydrogen combustion produces only water vapor as a byproduct, resulting in a much smaller carbon footprint.

Q: Can I combine electrical heaters and hydrogen burners for optimal heating performance?

A: Yes, combining electrical heaters and hydrogen burners can offer optimal heating performance by leveraging the precise temperature control and efficiency of electrical heaters with the clean combustion and sustainability of hydrogen burners, providing a flexible and environmentally friendly solution for tissue paper production.

Washable roof for a better work environment

The Advantage AirCap has an automatic washing system to remove dust from the hood roof, thus preventing the risk of fires. Not only does it provides you with a healthier and safer working environment, it also reduces downtime needed for cleaning and maintenance.

This can also be integrated with the Dry End Dust Cap washable roof of the Advantage WetDust system

The best drying uniformity and profiling capability with Advantage AirCap Heli

Valmet has developed a new Yankee hood which allows a perfectly even drying profile on one side and the possibility to correct a non-optimal moisture profile on the other. As a result, a better final product quality, with less converting problems and a higher profitability are achieved.

The arrangement of the crescent headers is normally oriented in Machine Direction. In the patented Advantage AirCap Heli the headers are tilted in Cross Direction. Therefore, the average drying intensity transferred to the paper is perfectly uniform in Cross Direction, thus eliminating the hood footprint in any working condition.

The new helical design determines a gradual average impingement speed variation with which the drying paper travels below the hood, as the crescent headers are at an angle and the paper always travels below two adjacent crescent headers.

Advantage BalanceControl™ (ABC)

The Advantage BalanceControl system allows the mill to maintain - in an automatic and continuous manner - the optimal settings of the air system, such as balance and exhaust humidity level, as well as to select the best drying parameters in the choice between temperature and impingement speed. The system constantly detects and adjusts the parameters, and the air system flows characteristics (air temperature, pressure, volume flow and humidity values) to fix and always maintain the lowest specific consumption costs required for the drying.

The automatic control can be accessed both locally and remotely and the settings are continuously adjusted to comply with the machine balance and the individual drying strategy. Real-time diagnostics and troubleshooting enhance an optimum machine operation and data are collected for further benchmarking activities.

The energy saving in turn leads to lower emissions and improves the environmental footprint of tissue production.

Saving potentials

Advantage BalanceControl, burners for alternative fuels, the waste heat steam generator and air to water heat recovery can help you save water, energy and reducing CO2. And therefore lower the environmental footprint in your tissue production. Get in touch with us and we can discuss more in depth what it could mean for your mill.

Contact us

|

Energy |

Water |

CO2 |

+ 500

Valmet Advantage AirCaps delivered world-wide