Forming roll covers for tissue machines

Improved reliability with wear and corrosion resistant covers

Roll covers operate in a wet, corrosive environment in the forming section of tissue machines. Valmet's roll covers deliver years of reliable performance along with product expertise throughout the lifespan of the roll cover.

Improved reliability

Long running times

Easy to keep clean

Best runnability with forming roll covers

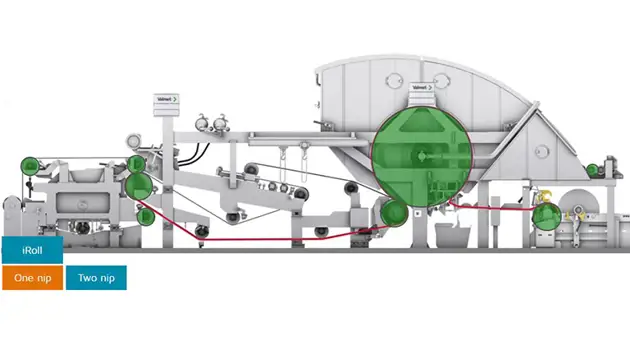

In the forming section of tissue machine the frequency of roll rotation is extremely high as the small rolls have to carry fabrics to reach the desired machine speed.

Demands for wear and corrosion resistance, cleanliness for long run times, and the best possible runnability have all been taken into account in the design of Valmet’s roll covers for forming section applications.

Various roll cover materials for tissue making

Valmet offers a variety of roll covers for your forming section, providing the properties you need to meet your high-quality tissue production targets. We have developed unsurpassed rubber compounds and composite covers as well as ultra-wear-resistant hard coatings for challenging conditions and demanding positions in all forming phases.

Want to talk to our roll service experts?

Answer a few questions and our roll experts will contact you shortly.

Contact us

Find optimal roll covers for tissue making

Browse this roll cover application tool and discover easily different roll cover options for your forming section applications in tissue machine.

Start exploringFind more detailed product information about forming roll covers

Drive Roll Cover DS (1)

iRoll technology (8)

iRoll Tension online tension measurement (2)

Lead Roll Cover GC (1)

Lead Roll Cover GM (1)

Lead Roll Cover JR (1)

Lead Roll Cover WGE (1)

Lead Roll Cover WJ (2)

Roll covers general material (6)

Spreader roll maintenance (6)