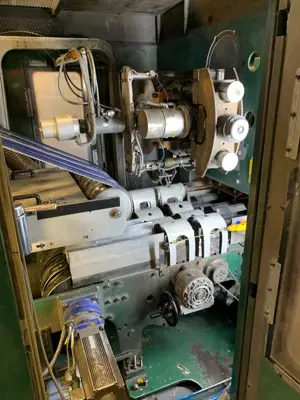

Casmatic CMW425 U0132

Casmatic

.To sell one wrapping machine CMW425, one bundler machine CMB202, and conveyors.

To sell one wrapping machine CMW425, one bundler machine CMB202, and conveyors.

CMW425 is a high speed wrapper (up to 180 p/1’) with max. flexibility on pack configurations.

The optimization of specific profiles for each movement, the adoption of new concept electronic safety systems allow the achievement of very high speeds with absolute security.

All machine movements are operated by servomotors: brushless motors driven directly all the movements.

General information

Main characteristics:

Patented rolls infeed system with constant pressure on product during the entire cycle and high tolerances.

Side folders with adjustable height for configurations with horizontal rolls.

Patented safety overhead flights chain system.

Pre-arrangement for on-line assistance.

Side sealing belts with automatic vertical movement to allow an uniform wear of the belts.

Casmatic CMB202 is a bundler for toilet or kitchen towel roll packs. Configurations are available in different sizes and formats in a variety of combinations, thus meeting all market demands.

The concept of Casmatic CMB202 is based on reliability to ensure long lasting technical operation. Easy to operate, the machine is equipped with the tool-free system for the format changes.

Furthermore, descriptive and visual instructions on panel guide the operator step-by-step.

The model Casmatic CMB202 is today the most versatile bundler available on the market as it is supplied with different feeding systems according to layout or production needs.

Machines are equipped with ContRoll harmonizing system.

Machines appear in good conditions, ready to place in production.

- Model/ year

N°1 CASMATIC CMW425 – 2005

N°1 CASMATIC CMB202 – 2005

Conveyiors

- Location

Industrial Park Ga-Rankuwa (South Africa)

Technical details

| Machine width | Line nominal width 2750 mm |

| Line composition |

|

| Optional/Upgrades installed |

|

| Electrical platform | Siemens S7, DC main motors |

| Type of products |

Toilet roll, Kitchen towel

|

| Speed/production rate | Maximum mechanical speed: 550 m/min |

Additional Information

| Optional/Upgrades available for installation |

|

Are you interested?

Please fill in the form for asking us more details about this proposal