Online condition monitoring

Valmet DNA Machine Monitoring

Valmet's renewed online vibration monitoring solution offers world-class diagnostics tools and automatic anomaly detection for early warnings of possible machinery faults. The Valmet DNA Machine Monitoring enables the use of both wired and wireless measurements. The solution is built in the Valmet DNA Automation System, enabling machine condition and process information to be flexibly utilized in the same user interface. The use of a single system significantly improves collaboration between operators and maintenance.

Seamless access to process and machine vibration data within the same system

Wired and wireless vibration sensors and other measurements within the same system

The leading vibration analysis tools with automatic anomaly detection

A single system enables collaboration

Condition monitoring and process information

The solution is built in the Valmet DNA Automation System, enabling machine condition and process information to be flexibly utilized in the same user interface.

The new Valmet DNA User Interface is available in a local network or remotely through a secure internet connection. Users can flexibly manage the process and maintenance information from the same system based on their user rights.

Automated anomaly detection

The leading vibration analysis tools

The renewed Valmet DNA Machine Monitoring features an automated anomaly detection, which monitors the key vibration parameters and provides early warnings for possible machinery faults. Human input or even preset alarm limits are not needed. The automated diagnostic application identifies fault types and severity based on measured vibration data. This allows users to focus on planning correct maintenance actions to improve efficiency and uptime.

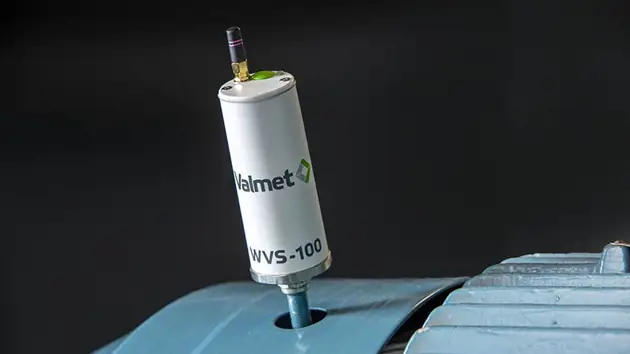

Wired and wireless

The right vibration monitoring solution for each machine

Valmet provides a wide range of vibration sensors for various machinery. In addition to traditional wired vibration sensors, Valmet now introduces several wireless vibration sensors and measurement modules. These can be divided into three categories: wireless piezoelectric accelerometers, wireless Micro-Electro-Mechanical Systems (MEMS) accelerometers and wireless measurement modules for external sensors.

Condition monitoring offering