Advanced process control and imaging systems for grate optimization

Combustion optimization solution for waste-to-energy plants

Valmet DNA Combustion Manager and Valmet Visible Thermal Imaging System join forces to revolutionize combustion optimization in waste-to-energy (WtE) plants. The combination of machine vision and advanced process control increases grate throughput, availability and safety, reducing emissions and auxiliary fuel consumption.

Maximized grate capacity and throughput without risk of overloading the grate

Fewer process disturbances – for increased plant availability

Reduced auxiliary fuel costs and emissions

Increased operational awareness and uniformity across shifts

Innovative grate combustion control

The state-of-the-art solution automatically controls the grate by section and provides tools to monitor the bed inventory. By stabilizing the controls and increasing control accuracy, the new maximum grate capacity can be achieved while mitigating the risk of its overloading.

The continuous HD-quality view of the grate enables operators to foresee potential process upsets and prevent unplanned shutdowns, which improves combustion control and increases plant availability. In addition, the system has built-in alarms that signal undesired combustion or alert if expected combustion does not occur, boosting overall safety. Finally, the enhanced fuel combustion efficiency and flame control require less support fuel and help reduce emissions.

Customer success story

A pioneering combination of advanced process controls and grate combustion vision software improves combustion management and availability as well as lowers support fuel consumption at the Tammervoima waste-to-energy (WtE) plant in Tampere, Finland.

Read moreReal-time flame data for optimal grate performance

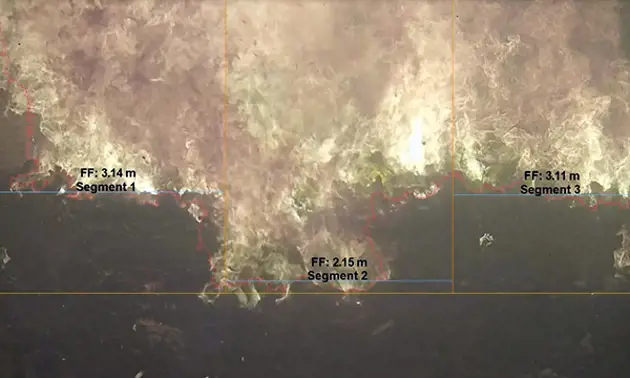

The Valmet Grate Combustion Vision application has been uniquely created for moving-grate boilers in waste-to-energy plants. The software application automatically detects the flame, measures the flame front location on the grate and presents the data in high-definition images. This real-time flame detection and monitoring allows operators to use the entire grate area minimizing the risk of overloading it.

Enhanced operational awareness

The application shows all essential data on an intuitive display in the local control room. This ensures operators identify process issues quickly and effectively. Additionally, the solution enhances operational awareness by providing in-depth insights into flame characteristics. This enables operators to observe real-time and historical effects of adjusting specific parameters. As a result, the solution not only narrows the experience gap between operators but also ensures more uniform performance across different shifts.

Improved efficiency with APC integration

Data from the new Grate Combustion Vision software is used by the Valmet DNA Combustion Manager advanced process control (APC) application. Valmet DNA Combustion Manager has proven successful in optimizing fluidized bed boilers (FBB) and grate-fired boilers in WtE plants. Now, the integration of Valmet Grate Combustion Vision software has introduced new and unique parameters enabling the safe maximization of fuel throughput. Based on process data, Valmet DNA Combustion Manager estimates the amount of fuel in each grate section. The APC also provides operators with automated responses to process disturbances, facilitating much faster recovery.

Process Performance Study to evaluate your potential

When aiming to enhance performance, Valmet Performance Study is an excellent starting point. This service assesses the potential for improvement within your processes, harnessing Valmet’s cutting-edge expertise. The study combines data analytics, on-site audit and camera tests conducted by Valmet process and boiler diagnostic systems specialists. As a result of the study, you will get a customized optimization concept plan with improvement recommendations, ROI calculation and cost-benefit analysis.

Would you like to find out more about our process optimization solutions?

Please let us know more about your needs – and our experts will contact you shortly.

Contact us