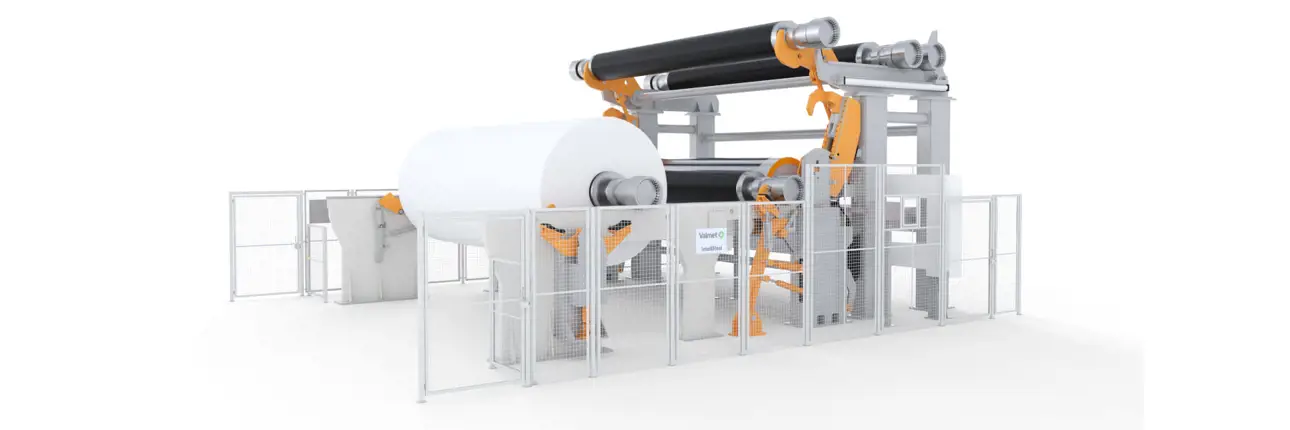

IntelliReel

The key to optimum parent roll control

The IntelliReel has a reliable and open structure which enables easy control over the reeling process. It is designed to provide precise, repeatable, efficient and safe paper winding. The IntelliReel operates with high efficiency, reaching optimal final product parameters. At the end of the process, a uniform parent roll is obtained and ready for converting operations.

Controlled nip throughout the winding process

Minimized winding defects & sheet loses

Easy process control as well safe & minimized maintenance

Tailor made solution

The principle of building the optimum parent roll structure.

The primary arms are equipped with a nip-relieving system that consists of hydraulic cylinders that counteract the weight of the spool and primary arm hook load. The purpose of nip relieving is to reduce the excessive weight of the spool and thus control the nip load between the spool and reel drum.

As the spool travels down with the primary arms on the reel drum surface, the pressure in the nip relieving cylinders is automatically controlled to achieve the desired nip load at all primary arm angles. The position of the spool on the drum is detected by an inclinometer mounted inside of the front side primary arm.

When the reel spool with the paper is transferred to the secondary arms, the reel automatically controls the transfer between the two sets of arms to avoid a potential double nip (controlled transfer).

The winding process in secondary arms is controlled with hydraulic cylinders and uses an inclinometer and proportional valves to control the nip pressure. The inclinometer monitors the secondary arm position throughout the parent roll build and sends this information to the PLC/DCS for proper control of the hydraulic pressure. Operators have the ability to adjust the nip pressure level at any time and can select the nip start and end levels.

How do you plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. Download our e-book to learn more.

Download e-bookPlanning a grade conversion?

The world is changing fast; the consumption of papers is decreasing and boards increasing. Update your paper machine with Valmet to produce more profitable products.

Discover moreLearn more about the services and automation solutions for reels

Explore our latest board and paper press releases

- Mar 27, 2025Valmet to supply two winders to Wuzhou Special Paper in China

- Mar 6, 2025Valmet to supply a high-capacity winder to Jingxing Holdings in Malaysia

- Jan 21, 2025Valmet to supply an off-machine coater to a customer in Asia-Pacific

- Nov 12, 2024Valmet to supply a complete papermaking line to one of its major customers in Asia-Pacific

- Oct 21, 2024Valmet’s change negotiations completed in Finland in its Paper business line’s Board and Paper Mills business unit

- Oct 3, 2024Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China

- Sep 5, 2024Valmet to start change negotiations in Finland in its Paper business line’s Board and Paper Mills business unit

- Aug 16, 2024Valmet and Spinnova Plc sign a partnership agreement regarding process equipment for textile fibre production

- Aug 1, 2024Valmet closes the agreement to acquire majority shares in FactoryPal, a subsidiary of Körber

- Jul 8, 2024Valmet to supply operator training simulator to Graphic Packaging International in Waco, Texas, United States