Broke system

Stable consistency

Improved end-product quality

Low fresh water consumption

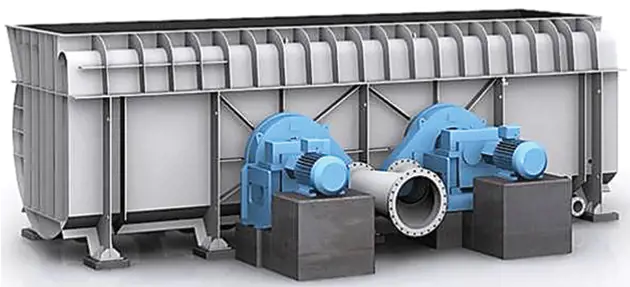

An essential feature of all paper machines is an efficient broke handling system. Along with favorable slushing efficiency, an ability to cope with variations in production rate is among the most important requirements. This is relatively simple at the wet end, where the sheet disintegrates easily, but dry-end trim and especially coated broke are more difficult to slush and may require separate deflaking and/or screening to remove impurities from the stock.

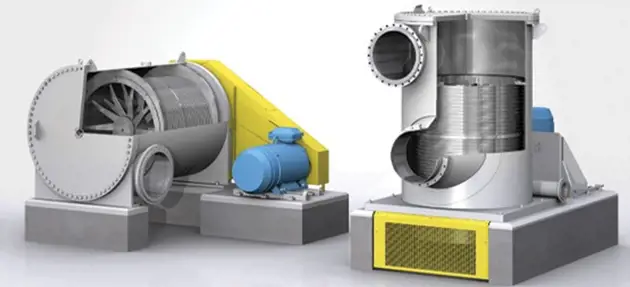

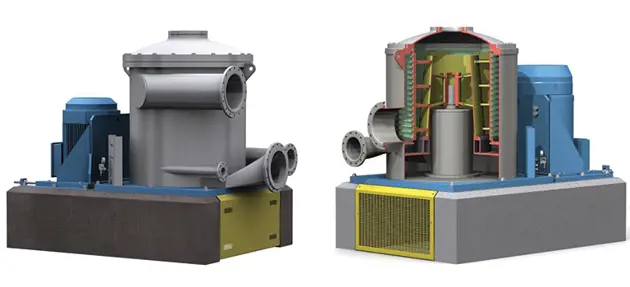

Broke Screening

Plastic, glass, metal, gravel, sticky particles, and more are all common impurities that can be found in the paper stock of a mill. If not removed, impurities and contaminants can damage equipment while also reducing the overall stock quality in a mill. To achieve target pulp quality with low operational fiber loss and costs, highly efficient screening is key.