Stonel™ Axiom™ AN / ANX

Highly reliable integrated discrete valve controller

The Stonel Axiom AN / ANX offers unmatched reliability using non-contact position sensing with solid state electronics and contaminant-tolerant pneumatic control. Coupled with its space-efficient design, corrosion resistance and optional networking, diagnostics and wireless link capability, it offers unrivaled convenience and cost-saving benefits in hazardous and general purpose process applications.

Magnetic drive eliminates wear bushings and offers ultra-high reliability

Universal voltage reduces inventory and enables easy standardization

Quick and convenient set-up with push button switch setting

Robust enclosure tolerates most process environments

Features

- Epoxy coated anodized aluminum enclosure (ANX)

- Epoxy coated anodized aluminum housing with Polycarbonate cover (AN)

- Universal voltage solenoid and switching

- Convenient push button switch setting

- Robust solenoid valve with standard rebreather

- Optional wireless access for configuration and diagnostics

- Advanced diagnostics with AS-interface (ASi-5). Diagnostics settings managed via Stonel Wireless Link app

- Space efficient design

- Rebreather system minimizes corrosive ingestion for single-acting actuators

- Bluetooth wireless access versions enable convenient trouble-shooting to anticipate problems, increasing plant uptime and reducing maintenance costs

- Compact design minimizes valve-actuator assembly dimensional envelope

Applications

- Automated on/off valve applications in hazardous process environments

- Corrosive and wash down process environments

- Chemical process

- Pharmaceutical and biotech

- Marine & offshore

- Oil & gas

- Agri-processing

Control and monitor an automated on/off valve in all process areas

The Axiom monitors and reports valve position with Visual indicator and signals to the controller. Features integral single or dual coil solenoid valves to control position of the actuated valve.

Convenient switch setting

The touch sensors have no moving parts; just hold your finger for two seconds on the button to set. The bright LED indication confirms that you have successfully set the position. Communication models allow you to configure and set the sensors using your smart phone or tablet; no cover removal needed!

Single or dual pilot configuration

Available in either single or dual pilot configurations. Dual pilot options are available for shuttle piston, fail-in-last position applications. Several external manual override options are also readily available. For special valve configurations with nonstandard manual override features, please consult factory.

Reliable position sensing

An extremely reliable solid state magnetic resistive (mag res) sensor detects the valve position by monitoring the orientation of a magnet attached to the actuator. This design is tolerant of lateral and vertical shaft movement, which may occur in heavily used actuators, without affecting rotational measurement.

High-visibility LED indication

Clearly view valve position status with the high-visibility LED indicators. The LEDs offer easy viewing from a distance with the high intensity lighting that can be identified even in sunlight.

Easy everything

An extremely reliable solid state magnetic resistive (mag res) sensor detects the valve position by monitoring the orientation of a magnet attached to the actuator. This design is tolerant of lateral and vertical shaft movement, which may occur in heavily used actuators, without affecting rotational measurement.

Specifications

|

AN35:

|

Universal voltage switching and solenoid

|

|

AN45:

|

Namur sensors (7-24 VDC)

|

|

Communication options:

|

AS-Interface and DeviceNet

|

|

Temperature range:

|

-40 °C … +80 °C / -40 °F … +176 °F

|

|

Material:

|

Epoxy coated anodized aluminum housing

AN: Polycarbonate cover

ANX: Epoxy coated anodized aluminum cover

|

|

Flow capacity:

|

0.8 Cv / 1.2 Cv

|

|

Hazardous area approvals: AN

|

Ex i, Class I, Division 1 (I.S.) and Class I, Division 2, see Approvals tab

|

|

Hazardous area approvals: ANX

|

Ex d, Ex i Class I, Division 1 (XP) and Class I, Division 2, see Approvals tab

|

Single or double-acting configuration

The same Axiom AN model is suitable for both single-acting/spring return (SR) and double-acting (DA) actuators. The standard rebreather capability for single-acting/spring return is built in.

Field configuration may be made by conveniently removing and reinserting the pneumatic plug for the appropriate actuator type.

Universal application

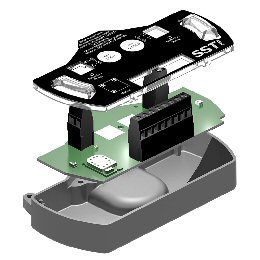

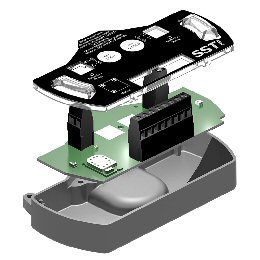

The Axiom is designed to readily adapt to most quarter-turn actuators. The mounting manifold system combines the mounting base and pneumatic manifold to minimize space and simplify installation. It attaches the Axiom directly to the actuator and ports air from the pneumatic valve to the actuator.

Included in the manifold system are:

1. Actuator shaft adaptor and fastener.

2. Epoxy-coated anodized aluminum mounting plate manifold with o-rings and stainless steel fasteners.

3. Pneumatic plug for SR/DA configuration.

The manifold system readily adapts to VDI/VDE 3845 sizes 1, 2 and 3. Special variations may be made for sizes 3, 4 and non-standard quarter-turn actuator mounting patterns.

Proven sensing and communication

The Axiom platform has all position sensing, communication or switching integrated into StoneL C-module. Users may set open/closed positions conveniently and accurately on all modules. And easy to view instructions, along with bold LED indication, are displayed on the module itself.

Continuous sensing with open/closed settings

The C-module (continuous sensing) integrates a magnetic resistive sensor system to monitor exact valve position throughout the rotational range. Touch-sensitive or remote open and closed position setting along with microprocessor based operation make this state-of-the-art system convenient, reliable, and smart.

Position settings are made using the touch-sensitive buttons on the module’s overlay. Simply operate the actuator to the open position (using standard internal manual override) and touch the SET OPEN button. Operate the actuator to the closed position and touch the SET CLOSED button. Position settings remain locked in when power is removed and reapplied.

Networking with wireless link

Both the AS-Interface and DeviceNet models offer dramatic installation cost savings and have optional wireless link, with an iOS app. The wireless link is also available for conventionally wired systems. This feature offers unrivaled convenience and maintenance savings during the automated valve’s entire life cycle. You may remotely access your valves from up to 50 meters, depending on obstructions.

Integral pneumatics

The Axiom’s pneumatic valve system consists of a solenoid pilot that drives the main high-flow spool valve. Pilots are automatically associated with the appropriate function selected.

Special features

- Solenoid pilot and main spool design offer long life, exceptional tolerance to dirty air, and tight shut-off.

- Universal voltage solenoid system may be used for standard AC or DC applications.

- Five-way, two-position spring return configuration may be used for either single- or double-acting actuators. Dual coil shuttle piston versions are also available for fail-in-last position.

- Rebreather channels exhausted air from pressurized side of actuator into spring side, preventing ingestion of contaminated air from the environment that may corrode springs or actuator internals.

Models

Single or double-acting configuration

The same Axiom AN model is suitable for both single-acting/spring return (SR) and double-acting (DA) actuators. The standard rebreather capability for single-acting/spring return is built in.

Field configuration may be made by conveniently removing and reinserting the pneumatic plug for the appropriate actuator type.

Universal application

The Axiom is designed to readily adapt to most quarter-turn actuators. The mounting manifold system combines the mounting base and pneumatic manifold to minimize space and simplify installation. It attaches the Axiom directly to the actuator and ports air from the pneumatic valve to the actuator.

Included in the manifold system are:

1. Actuator shaft adaptor and fastener.

2. Epoxy-coated anodized aluminum mounting plate manifold with o-rings and stainless steel fasteners.

3. Pneumatic plug for SR/DA configuration.

The manifold system readily adapts to VDI/VDE 3845 sizes 1, 2 and 3. Special variations may be made for sizes 3, 4 and non-standard quarter-turn actuator mounting patterns.

Proven sensing and communication

The Axiom platform has all position sensing, communication or switching integrated into StoneL C-module. Users may set open/closed positions conveniently and accurately on all modules. And easy to view instructions, along with bold LED indication, are displayed on the module itself.

Continuous sensing with open/closed settings

The C-module (continuous sensing) integrates a magnetic resistive sensor system to monitor exact valve position throughout the rotational range. Touch-sensitive or remote open and closed position setting along with microprocessor based operation make this state-of-the-art system convenient, reliable, and smart.

Position settings are made using the touch-sensitive buttons on the module’s overlay. Simply operate the actuator to the open position (using standard internal manual override) and touch the SET OPEN button. Operate the actuator to the closed position and touch the SET CLOSED button. Position settings remain locked in when power is removed and reapplied.

Networking with wireless link

Both the AS-Interface and DeviceNet models offer dramatic installation cost savings and have optional wireless link, with an iOS app. The wireless link is also available for conventionally wired systems. This feature offers unrivaled convenience and maintenance savings during the automated valve’s entire life cycle. You may remotely access your valves from up to 50 meters, depending on obstructions.

Integral pneumatics

The Axiom’s pneumatic valve system consists of a solenoid pilot that drives the main high-flow spool valve. Pilots are automatically associated with the appropriate function selected.

Special features

- Solenoid pilot and main spool design offer long life, exceptional tolerance to dirty air, and tight shut-off.

- Universal voltage solenoid system may be used for standard AC or DC applications.

- Five-way, two-position spring return configuration may be used for either single- or double-acting actuators. Dual coil shuttle piston versions are also available for fail-in-last position.

- Rebreather channels exhausted air from pressurized side of actuator into spring side, preventing ingestion of contaminated air from the environment that may corrode springs or actuator internals.