On a journey to transforming paper quality

Jun 26, 2024

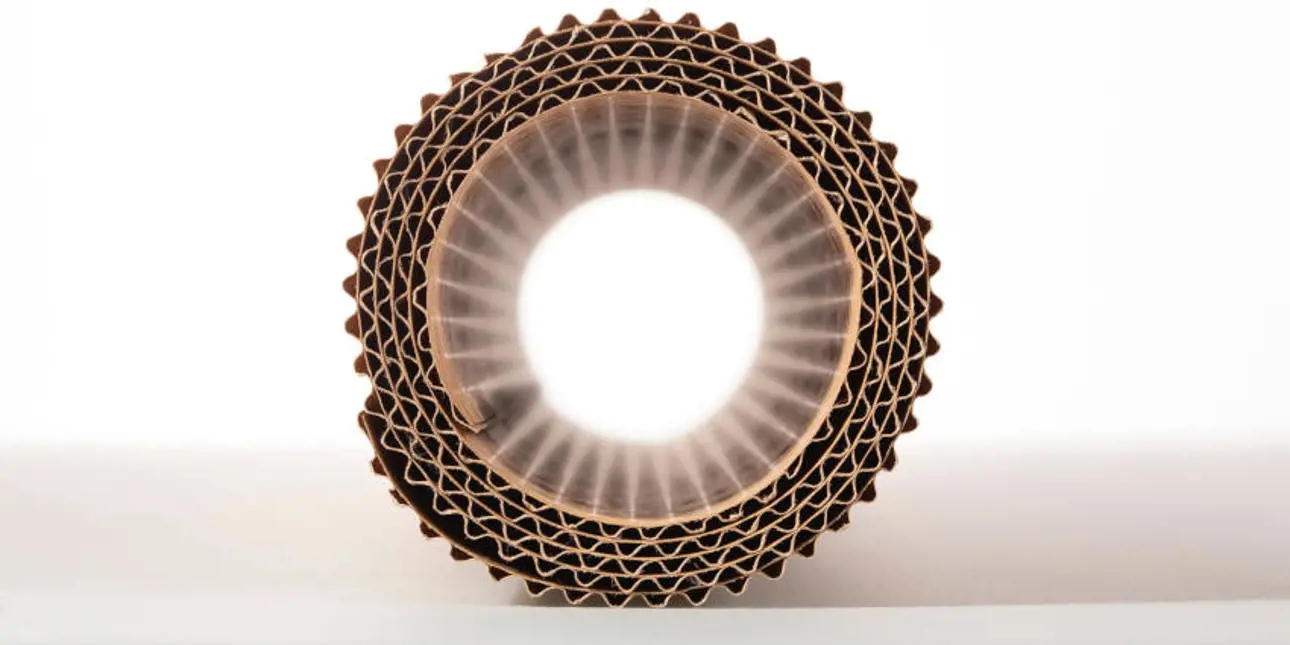

The installation of a new headbox, a new shoe press, and a quality scanner at PM 6 has helped South India Paper Mills Ltd. (SIPM) produce a higher quality corrugated board to meet the needs of paper converters.

South India Paper Mills Ltd. (SIPM) is located 150 km from Bangalore, near Nanjangud in the state of Karnataka, India. They are a significant player in the paper industry, focusing on the container board segment. With over six decades of experience, SIPM has continually adapted to industry dynamics to meet changing market demands. In a recent interview with Mr. Manish Patel, owner and Managing Director of SIPM, we discussed their transformative journey, strategic investments, and successful collaboration with Valmet.

Rising standards of paper quality in the Indian corrugated board conversion market

In the Indian market, there have been significant investments in high-end converting machinery, which can be seen in the rising paper quality standards and productivity. “From 2007 onward, the container board conversion industry has seen tremendous change,” says Mr. Manish Patel.

These changes have made it possible to produce a better quality product, which has correspondingly provided opportunities for nicer graphics and printing. SIPM began the production of corrugated boxes in 2009. This led them to identifying a crucial target – there was a need for higher quality paper in the segment so that converters could produce boxes that matched global standards.

Major steps toward transformation

To deliver the kind of paper that the converters in the industry needed, SIPM made the strategic decision to make a large investment in PM 6. With this investment, SIMP aimed to improve paper quality, boost productivity, and save energy costs. They decided to cooperate with Valmet because of the new technologies they could offer and their commitment to innovation, quality improvement, and sustainability in the container board conversion industry.

SIPM made the strategic decision to invest in PM 6 to deliver the kind of paper that converters needed.

SIPM identified key areas such as the headbox and the shoe press in which they could optimize their paper production processes. The scope of supply included an IntelliJet V Headbox, IntelliPress Linear, and a Valmet IQ Scanner to facilitate excellence in paper production. Valmet’s advanced technologies not only improved paper quality but also reduced energy consumption and production costs.

The IntelliJet V Headbox helps improve the productivity of the converter and brings value in terms of energy efficiency, which leads to cost savings.

Deep expertise and timely assistance

Despite challenges connected with the Covid-19 pandemic and travel restrictions, SIPM’s collaboration with Valmet ensured a smooth start-up of the new machinery. Admittedly, the installation and commissioning process was delayed, but SIPM appreciated the exceptional support from Valmet’s local team. With Valmet’s expertise and timely assistance, they successfully achieved operational stability.

Mr. Manish Patel, owner and Managing Director of South India Paper Mills Ltd.

SIPM is continuing their transformative journey, focusing on optimizing production processes, enhancing product quality, and driving innovative solutions. Their commitment to excellence is propelled with advanced expertise and a proactive approach, and they are continuously exploring future opportunities. Their strategic investments and cooperation with Valmet highlight their commitment to innovation, quality, and sustainability in the container board production landscape. With a clear vision and determination, the company can lead the way to creating growth and value.

Text: Monika Cieślak, Weeraya Netwong, Akhil VP

Photos: Kartikaya Nagar

Related articles