Chip Bin DB

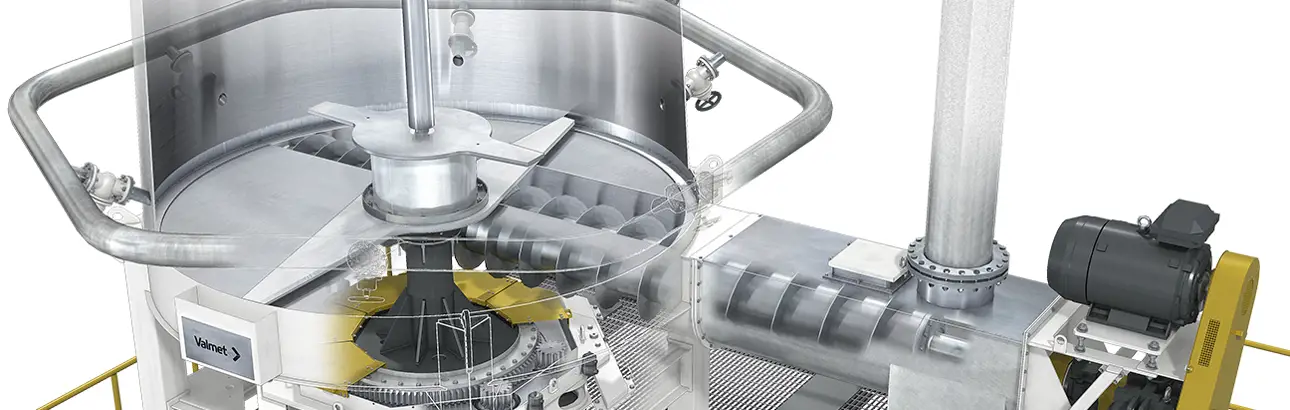

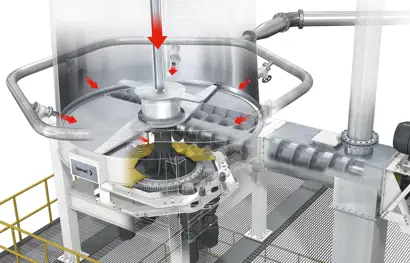

Valmet Chip Bin DB is a agitator equipped flat-bottomed chip bin fitted with a screw conveyor for an actively controlled discharge of raw material. The chip bin is suited for wood waste materials that are difficult to feed and have bridging tendencies.

The bin features a slightly conical upper shell narrowing towards the top and with one central and multiple peripheral insertion points for adding steam. The Valmet Chip Bin DB is highly suitable to use for pre-steaming of the chips.

An agitator rotates in full revolutions along the bottom to avoid any stagnant material that may cause unwanted build-ups and bridging problems. The design of the agitator and continuous rotation of agitator are crucial for smooth feeding and even presteaming of the raw material.

The agitator directs the material towards the discharge screw which can be fitted with a dewatering box to further optimize the dewatering performance of the plug screw feeder. This will result in less moisture entering the dryer.

Live bottom vs Valmet Chip Bin DB

The design of Valmet Chip bin DB is a direct counter to the many problems with typical live bottom bins. Live bottom bins was previously offered by Valmet, but has been phased out due to a number of problems.

|

|

| Live bottom bin | Valmet Chip Bin DB |

| Small volume | Big volume |

| Poor steam distribution | Fewer moving parts |

| Many moving parts/screws | Heavy duty parts |

| High maintenance cost | Good steam distribution |

| Cheap to buy as it often has weak structures manufactured from thin plates | Expensive in purchase, but lower cost in the long run |

Material available for download |

||

|---|---|---|

| Valmet Chip Bin DB | ||

Our expertise is at your service

Our focus is to bring your performance forward utilizing our extensive experience and in-depth knowledge of pulp process technology. Get in touch with our experts through your local Valmet office, or the link below.

Contact us