Valve and pump services

Reliability is at the core of every successful process plant’s operations. We are your reliable partner for flow control services.

ServicesFilters

Valve and pump services

Reliability is at the core of every successful process plant’s operations. We are your reliable partner for flow control services.

Services

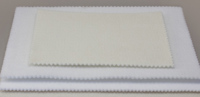

Clothing/padding for chest ironers and presses

Services

Rod beds

Rod beds are characterized by three attributes: reliability, performance and reusability. By reliability we mean better and more stable runnability for your process. Performance includes long a lifetime with excellent results. Reusability means less waste and significant cost savings.

Services

Spare parts

Ease of purchase, reliable and prompt logistics and information sharing are all key requirements for the efficient management of spare parts.

Services

Spare parts for cooking and fiberline

High-quality Original Equipment Manufacturer (OEM) spare parts, upgraded parts, and retrofits to restore normal equipment or system operation. We offer daily spare parts, parts for shutdowns, and comprehensive spare part packages in connection with capital projects, all complemented by convenient online purchasing.

Services

Maintenance development and outsourcing services

Valmet provides a wide range of maintenance outsourcing services for pulp an paper mill's. We give the mill one contact for all maintenance operations and allow it to focus on its core business.

Services

VII for Energy Efficiency

How can I use the Industrial Internet to reduce energy consumption and keep energy-related costs down?

Services

Grinding services

Valmet's roll grinding services provide precise profile and roundness shapes for roll and cylinder surfaces for board and papermaking. Maximizing the roll grinding precision means extended roll running times and minimal vibration.

Services

Screen baskets

Whether your approach screens at the board or paper machine are slotted or hole, we tailor solutions for your needs. For better energy efficiency, all slotted approach screens should be equipped with Valmet’s latest technology invention, flow screen baskets, resulting in higher capacity, lower string tendency and higher screen efficiency. By maximizing the screening performance with hole baskets, we tailor the drilled basket hole pattern and profile to your specific requirements. For reject positions, we offer long-life slotted and hole screen basket solutions that secure the best availability and fiber savings.

Services

Industrial Internet

Let’s have a dialogue with data to improve the performance of your mill! Valmet Industrial Internet offering (VII) covers an extensive range of solutions and applications for board and paper mills.

Services