Success with the Valmet Acoustic Pyrometer at the Xinyuan Power Plant

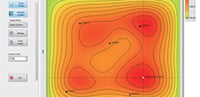

The continuous measurement of full load furnace temperature is a difficult problem that Xinyuan power plant solved by installing Valmet acoustic temperature measurement system.

Reference