Tissue mill process and production optimization

Analyze and study the tissue production line to improve productivity, optimize performance and reduce operating costs

Study production line’s current condition, performance and improvement potential by performance monitoring, data analysis, trials and e.g. process stability studies and audits. On-site or remote support and guidance given by our experts to support the operations team in production development and/or equipment process tuning during operations. Experts also support optimizing the performance and lifetime and related problems of fabrics, rolls equipment and parts.

A global network of expertise with vast database of benchmarked information for high-technology equipment and processes. Thorough analyzes of the current condition of processes and machinery can improve runnability, efficiency, production quality and reduce operating costs.

Our offering for process support and optimization include studies and audits, competence development, environmental services, advanced process controls and performance agreements for maximized process performance.

Tissue producers typically need to push production and profitability even further without entering into major investments, as production and quality targets need to be met with lowest possible raw material and energy consumption. Our goal is to support your competitiveness and to provide support throughout the lifecycle, such as enhancing the mills' environmental monitoring system for detecting sustainability issues at an early stage. The scope of our optimization services is always tailored and based on your specific needs.

Read more about our solutions from Valmet Tissue Services Offering catalogue

Studies provide deep insight for decision-making

When you are planning to reach new levels of productivity , in-depth studies reveal the modifications or investments needed to reach these goals. Studies consists of a number of tests, theoretical analyses and reviews that can be performed on your entire production line. Analytical findings reveal bottlenecks and can support your mill’s decision making in future upgrades, rebuilds and larger investments. Careful studies lead the way to improving overall production line capacity and provide information for further actions.

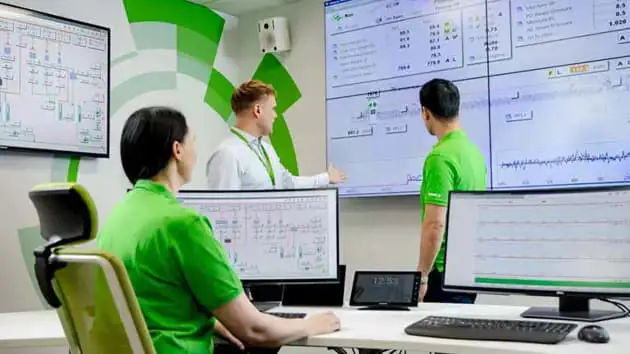

Optimizing tissue machine performance with data driven analytics

Valmet Machine Diagnostics gives detailed insights into your machine performance. With reliability agreement we collaborate to help avoid unplanned stops and improve service and maintenance predictability. By utilizing the data from your process, Machine Diagnostics gives you useful production insights, and helps you to understand the improvement potential. Machine Diagnostics is remotely connected to our Valmet Performance Center. Our support specialists continually keep track of your performance and react to any issues immediately. They study each case and get back to you with proposed solutions, so you can take immediate action and never skip a beat in production. Indicators are available for different sections of the tissue machine such as former, press, drying, sizer, calender, sizer and reel.

Audits for performance improvements and troubleshooting

Detailed audits help to reveal the current status of machinery and processes and to determine the maintenance actions required for continuous performance improvements. Audits tackle issues with energy consumption, efficiency and runnability, as well as identifying bottlenecks, stability and quality problems, functioning as beneficial troubleshooting tools. Our audits include a comprehensive list of recommendations for reaching potential operating cost reductions and environmental targets.

Process and optimizations services

- provide in-depth knowledge to support investment decision-making

- offer experts’ analysis on current situation along with detailed recommendations

- reveal bottlenecks and restrictions in the production line

- uncover possibilities for improving quality and productivity

Questions about your production line’s performance and improvement potential?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usBenchmarking to understand improvement potential

Benchmarking is a useful technique for measuring and improving your performance in various aspects of your business. It can help you to identify your strengths and weaknesses, set realistic goals, and learn from the best practices of others. As a tissue maker you can benchmark your production, quality, efficiency against others. With data discovery we can help you find solutions to known problems or identify improvement potential in operations or asset performance.

Find your mills energy saving potential!

In a tissue machine about 70% of the total energy is used for drying. A correct setting of hood and air system boosts production, quality and energy savings. Valmet technicians can support your mill in adjusting and finding the best machine settings. An audit reveals issues before affecting production, maintains correct balance in the hood, reduces fire risk, and improves machine efficiency. An audit offers a quick return on investment, providing advice on next steps. You can read more about our drying section performance agreement.

Explore: Drying Section Performance Agreement aims for increased safety and sustainability

References and articles