Suction roll seals for board and paper machines

Save more in energy than the cost of the seals

Valmet Seal Strips save energy and provide more stable wear resistance under demanding operating conditions than any other seal strip material in the market

Long seal lifetimes

Superior and safe handling characteristics

No breakage during handling or installation

Fast conformation to the shell surface

Resulting in rapid establishment of the required vacuum level

Energy savings

with correct seal construction and materials

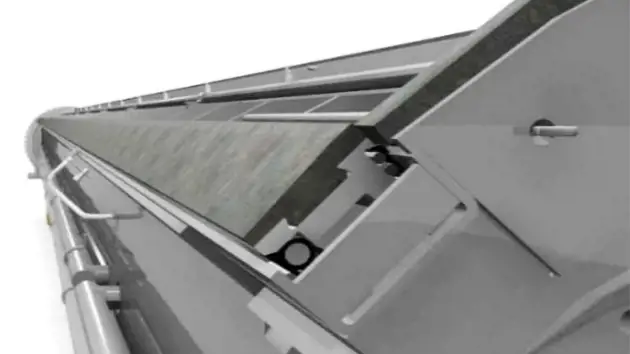

Improved suction roll performance

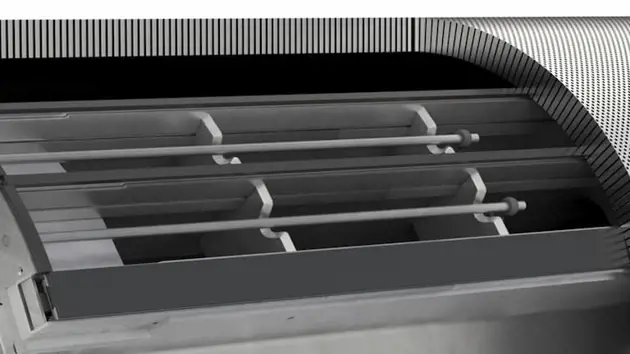

Roll seals are traditionally replaced every time a suction roll is serviced. Board and paper makers meet issues like fast wear and rigid and brittle materials that lose their properties at elevated temperatures. To eliminate these sealing problems and save on production costs, hundreds of mills all over the world have started to use Valmet Seal Strips in their suction rolls. Our seals are available for all OEM suction rolls and we have optimal seal material for each roll application.

It is really flexible!

Valmet Seal Strips Flex and Coldflex (acquired Coldwater) are cost-effective suction roll seal strips that deliver premium quality and performance. True to their names, they quickly conform to the inside of the suction roll shell. They are made of wear-resistant and low-noise rubber-graphite compound and can be used at all suction roll seal positions. They are the standard material for all new Valmet suction rolls, as well as for roll service and spare part deliveries.

Do you have any questions?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usProven performer

A rubber graphite-based Seal Strip Classic has been in use worldwide for over 30 years. Seal Strip Classic is also known with other product names like: BelSeal, ValSeal and JoSeal.

There are thousands of successful customer deliveries with Seal Strip Classic throughout the years. Classic material is homogenous, and it will not delaminate during the operation. High graphite content of the material gives a good gliding property to Seal Strip Classic. Seals will confirm quickly against the roll shell and shell is easy to rotate.

Improved performance in dry running conditions

To save costs, today's paper and board mills use less fresh and filtrated water. Re-wetting of the web at the press section is sometimes a problem, which means suction roll seal lubrication water cannot be used. Traditional axial sealing materials do not stand harsh and hot conditions when the suction roll is operated without seal lubrication. Valmet Seal Strip Dry is an improved seal strip material that withstands better dry running conditions.

Reduce your procurement costs with Valmet Seal Strip supply agreement

If you want to take your performance even further, we offer continuous support with consumables agreements. Transfer the stocking responsibility to us and reduce your networking capital and procurement costs.

Further strengthening OEM expertise

Acquiring Coldwater has enabled us to expand our suction roll seal offering and further strengthened product portfolio.

Read more about our OEM partnerships.