Cleaning solutions for board and paper making

Better automatic cleaning for fabrics and rolls

If your target is to produce a uniform, high-quality web, having a clean machine is essential. Our family of cleaning devices helps you to keep your fabrics and rolls clean during production. The benefits of effective cleaning are reduced break and a more stable process. Our cleaning solutions are easy to operate and maintain, and they are adjustable for a variety of cleaning needs. They are also environmentally friendly as there is no need to use cleaning chemicals.

Less sheet breaks

Increased productivity and uptime

Maximized lifetime and performance

Continuous roll cleaning during production

Direct contact with the web exposes smoothing presses to dirt, dust and other substances from the web. Our smooth press roll cleaner keeps your smoothing press clean during production. It has several benefits like clean rolls, no doctoring, no roll damage and the maintenance can be carried out during machine operation.

Continuous fabric cleaning during production

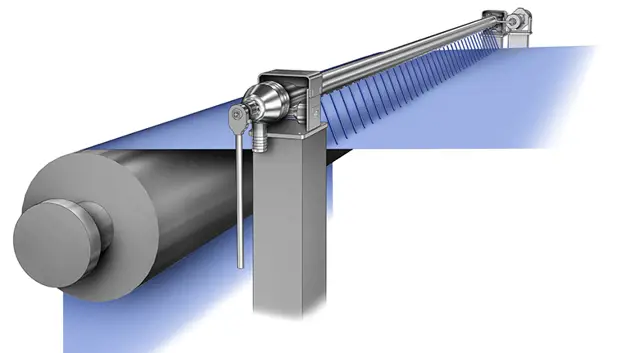

For fabrics, the increased use of recycled furnish means more contaminants, such as stickies. Our cleaning solution for fabrics improves end product quality through cleaner fabrics. Forming fabric cleaner is a continuous forming section fabric cleaner that operates during production. It uses powerful water jets to remove contaminants from the fabric. The high-pressure, low-volume nozzles provide efficient, thorough cleaning. It has much lower water use than conventional shower pipes. The fabric permeability remains at the desired level and maintenance can be performed during machine operation

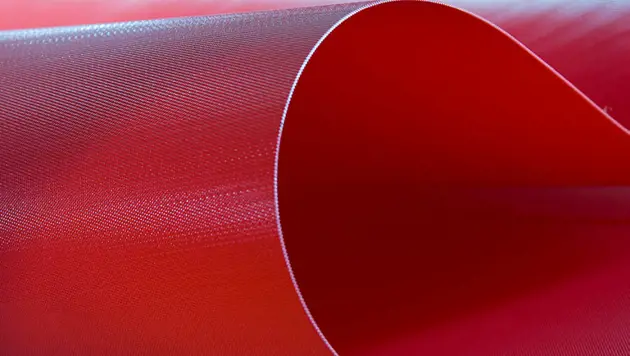

A clean transfer belt during production

Direct contact with the web exposes transfer belts to dirt, dust and other substances from the web. The transfer belt cleaner keeps the transfer belt clean during production. Which means no marking, better runnability and fewer washing breaks. It generates much lower water use than conventional shower pipes. Maintenance can be performed during machine operation.

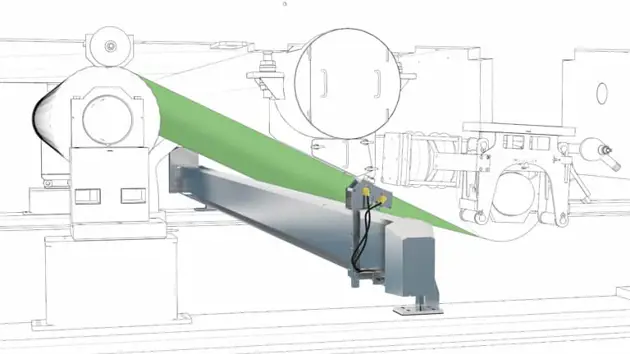

Increased uptime and maximized lifetime

Our latest fabric cleaner, dryer fabric cleaner, is designed for dryer fabrics. It increases machine uptime and maximizes the lifetime of your dryer fabrics. The fabric is cleaned on the paper web side with a high-pressure water jet. Unwelcome wet streaks are prevented with an air comb that blows the remaining moisture off the fabric. For optimum cleaning results, dirt and water mist are conveyed out of the machine to a cyclone separator. The fabric permeability remains at the desired level. It has a low energy consumption and has a maintenance-friendly construction.

Continuous forming fabric cleaner

Requirements for constantly improving the performance of paper and board machines is characterizing today’s papermaking. Valmet Forming Fabric Cleaner is a true continuous forming section fabric cleaner operating during production. It also provides reliable cleaning for press section transfer belts. Valmet Forming Fabric Cleaner keeps fabric permeability at the desired level and significantly improves the permeability of old fabrics. The device reduces misting and there is no need to use cleaning chemicals with the forming fabric cleaner.

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usReferences and articles