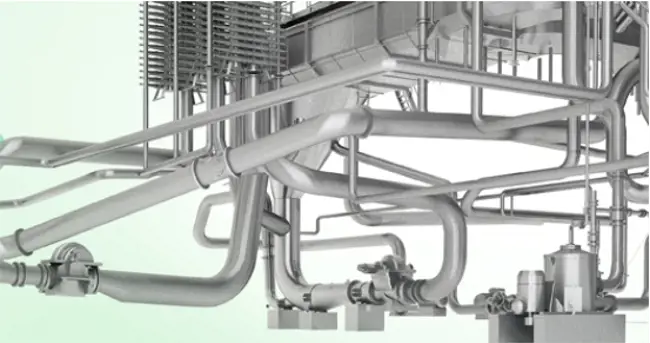

Chemical systems improvements for board and paper making

Customized solutions to ensure better operational reliability and provide a good return on your investment

Chemical systems improvements help you to ensure that your chemical systems are performing at the highest possible level. With the customized solutions you will improve paper quality, solve runnability problems and ensure better operational reliability. You can also expect measurable results, a good return on your investment and cost-effective.

Improve paper quality

Better operational reliability

Enable low-carbon production

Improve runnability

Do you want to move towards low-carbon production

Valmet Enzymatic Starch Cooking ZE is a patented starch cooking process for board and paper makers which is designed for starch quality and stability and where process environmental sustainability is crucial. It consists of two separate preassembled units for dissolving and cooking of surface size starch and binder starch. With the built-in heat recovery and new circulation system, it decreases energy consumption and decreases load and cost for water treatment. The new starch circulation system enables starch powder savings of several tonnes per month and decreases the load and cost for water treatment.

Modular process for white water treatment

Valmet Ultrafiltration W process is a solution for paper and board mills to produce colloidal, bacteria-free, ultrapure water from the white water. The main targets are reducing fresh water consumption, improving paper machine runnability and production efficiency, and controlling the energy balance. When a paper machine's showers and process stay clean for a longer time, the need for shutdowns is reduced. This has a significant effect on paper machine efficiency and product quality. A higher process temperature increases drainage, allowing increased paper machine speed and results in increased productivity. Water recycling allows the recovery of heat and raw materials. Valmet Ultrafiltration W helps to enhance the positive effects of recycling.

Ensure clean starch circulation in size press operations

The Valmet Starch Cleaning Booster is an innovative solution designed to prevent the accumulation of dirt particles in size press starch circulation systems. This system is essential for maintaining the quality and efficiency of the sizing process. The starch cleaning booster offers several key benefits such as enhanced screening, space efficient design and automatic backflow washing. The system can be installed while the machine is running, minimizing downtime, and ensuring continuous operation. The starch cleaning booster operates without disturbing the existing sizing process, guaranteeing no pressure variations at the sizer. The typical scope includes a centrifugal pump, OptiScreen RF pressure screens, precise instrumentation, and expert engineering support.

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usSafe and secure machine operations

We offer solutions for every application, from raw material handling to screening coating color in the supply system. Our machine controls are based on our solid process know-how and machine development expertise. Together with our industry-leading measurements and actuators, the foundation for machine control couldn't be any stronger.

Discover Valmet DNA Automation System for Machine Control

Read more about topics related to chemical systems