Dryer improvements for board and paper making

Customized solutions will provide a good return on investment

How can a customized dryer solution reduce your costs per tonne produced? By improving the drying efficiency and save energy, solve runnability problems, fix sheet moisture profiles, and ensure better operational reliability. This will also provide a good return on your investment.

Improved drying efficiency

Improved runnability

Process optimization

Discover the improvement process

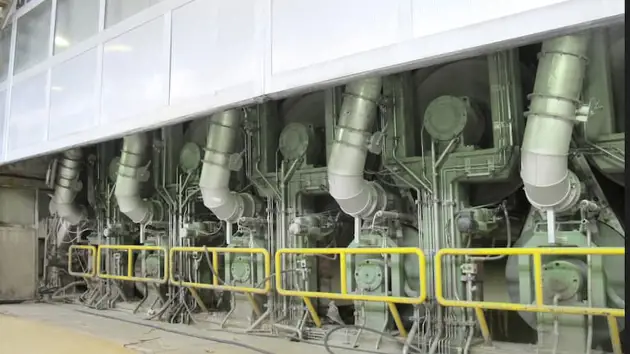

Drying efficiency improvement solutions are targeted to maximizing the drying efficiency and capacity of your dryer section.

Runnability improvement solutions address tail threading and runnability problems in the dryer section area and increase your production efficiency.

Profile management helps to maintain even moisture profiles throughout your dryer section.

Condition management is designed to keep your dryer section in optimal shape and clean for high production efficiency and availability. Systematic planning and prioritizing will cut your maintenance costs.

Boost efficiency with Valmet Web Stabilizer SR

Valmet Web Stabilizer SR* blow box is a dryer section runnability concept for single-felted dryer groups. They are typically installed in conjunction with grooved rolls or vacuum rolls and can be applied for both paper and board machine concepts having single-felting. The blow box concept offers excellent sheet stability, better energy economy and improved productivity. This is partly due to the blowing nozzle construction which has made it possible to reduce the blowing air amount remarkably leading to improved energy economy and smaller ducts and fans.

Excellent sheet stability with Valmet Hirun Web Stabilizer

At the beginning of the dryer section, the web dries rather slowly. This means that, with increasing machine speeds, it becomes more difficult to maintain web stability. Valmet Hirun Web Stabilizer system concentrates on solving special runnability problems on first dryer groups. The web release from the dryer cylinder is facilitated by means of a very powerful vacuum area. Valmet Hirun web release zone guarantees that the web and the tail will follow the dryer fabric in all running conditions.

Doctor blade change on a running machine

This patented technology is designed for board and paper machines, specifically in selected positions within the dryer section. Key features:

- Enhanced Safety: The blade is always protected, ensuring a safe operation.

- Quick Blade Change: The process takes less than five minutes, minimizing downtime.

- Comprehensive Service: Valmet offers a full scope of delivery, including installation.

Previously, replacing or cleaning doctor blades required shutting down the machine, leading to lost production time. Valmet’s solution allows for blade changes without stopping the machine, maintaining continuous operation and efficiency.

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usReferences and articles

Start the discussion about process upgrades

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}