Electrostatic Precipitator (ESP) Services for energy and pulp production

Efficient emission control with professional inspection and maintenance services, shutdown management, refurbishments, and upgrades

Our comprehensive ESP services ensure improved capacity and equipment availability as well as increased lifetime for electrostatic precipitators (ESP) at energy and pulp mills. We offer inspection and maintenance services, shutdown management services, refurbishments and upgrades, and electrical maintenance together with ESP control system upgrades and convenient spare part deliveries for all ESP’s regardless of the original manufacturer.

Improved capacity and equipment availability for efficient emission control

Preventive maintenance to avoid costly unexpected shutdowns

Increased equipment lifetime

Increased ESP efficiency for optimal performance

Do you know the condition of your ESP?

Preventive maintenance helps energy and pulp producers to avoid costly unplanned shutdowns. To plan preventive maintenance successfully, it is important to know the ESP’s current condition.

Valmet offers mechanical inspections during shutdowns, operational inspections during operation, and a wide range of remote process analysis and support services via Valmet’s Industrial Internet. We are experts in troubleshooting, site audits and process studies, as well as ESP efficiency and flue gas distribution measurements – regardless of the ESP’s original manufacturer. How can we help you?

Maintaining and improving the ESP performance through refurbishments and upgrades

After evaluating the equipment’s current condition and future needs, we propose the best technical solution to refurbish or renew your ESP. The customer needs are always discussed prior to the proposal – are you looking for a complete renewal with newest technology or will a refurbishment utilizing existing equipment be a better option?

Sometimes the ESP has reached the end of its lifecycle, or there has been a change in operation conditions such as dimensioning load or new emission regulations. Whatever the case, our expertise will help energy and pulp producers choose the right solution.

Get technical specifications, request a quote, or discuss solutions

Fill in the contact form and our experts will contact you shortly.

Submit your inquiryESP shutdown services for improved reliability

Valmet’s comprehensive shutdown services include shutdown planning, maintenance and replacement of internal parts of your ESP. Repeated regularly, well-managed and efficient shutdown services improve the reliability of your ESP and keep your equipment in optimal condition year after year.

Throughout the shutdown, our on-site professionals are supported by a wide network of technology experts from Finland, ensuring you have the necessary expertise at your service at a cost-competitive price.

Performance agreement gives you an easy access to Valmet’s ESP services

Many pulp and energy producers appreciate the opportunity to rely on our professional support, ensuring the optimal performance of their ESP both in the short and in the long run. They choose the Performance Agreement for Electrostatic Precipitator Services.

The agreement is always tailored to fit the customer needs. It can include plant development to ensure continuous improvement, Valmet Industrial Internet Services with on-demand support, regular condition assessment and reporting including recommendations for further actions and spare parts management. All for improved and reliable performance and long lifetime of the ESP.

Related content about air emission services for pulp mills and energy plants

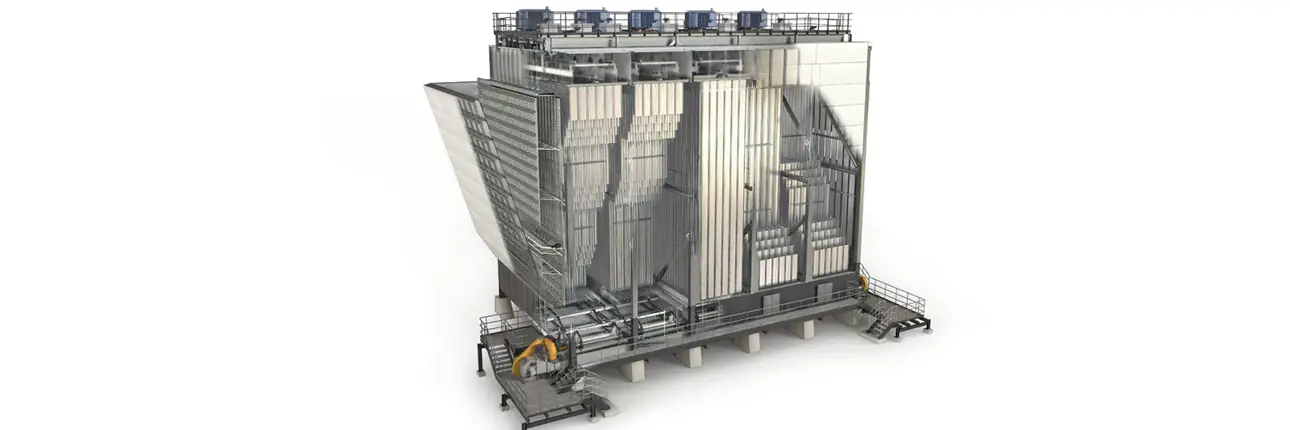

An electrostatic precipitator (ESP) removes fine particles, such as dust, from a flue gas by charging the particulates electrically and collecting them collecting plates.

Thanks to Valmet’s long experience in designing, manufacturing and maintaining electrostatic precipitators for small scale heat plants to large recovery boilers, we are the experts in various services tailored to maintain and improve the ESP performance at pulp and energy plants. In general, our customers appreciate the reliable and efficient performance of their equipment, which can be achieved through our ESP services.

Through our comprehensive service portfolio, we ensure improved capacity and equipment availability as well as increased lifetime for electrostatic precipitators (ESP) at energy and pulp mills. We offer inspection and maintenance services, shutdown management services, refurbishments and upgrades, and electrical maintenance together with ESP control system upgrades and convenient spare part deliveries.

We understand that many of our customers are striving to comply with the tightening regulation for air emissions, and we want to support them in securing their emission-related targets. That is why we are committed to providing the best possible solutions to help our customers achieve the optimal efficiency, reliability, and performance of their ESP. Our team of experts is always available to support our customers with their needs.

Contact us today to learn more about our products and services and how we can help you achieve your production goals.

Start the discussion about Electrostatic Precipitator Services for pulp and energy production