Air drying plusses: Higher sheet quality and 50% lower energy costs

Jun 9, 2011

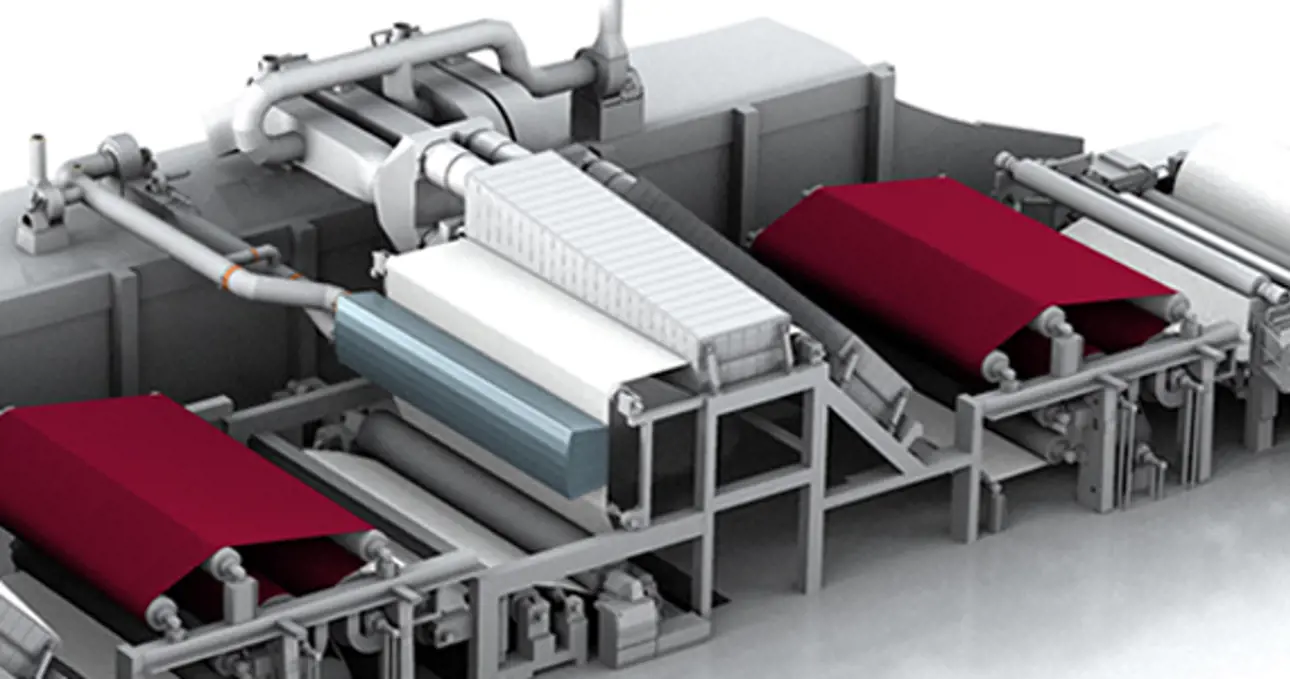

During the past few years, energy-conscious papermakers have shown that even the best coated paper and board quality can be produced energy-efficiently with Valmet’s*) OptiDry Coat air dryer. It has outperformed the infrared (IR) dryer that has been commonly used as the first dryer after the coating station. In this machine position, a one-sided, compact dryer with a high energy output is needed.

The OptiDry Coat air dryer is based on Valmet’s modern patented nozzle technology, in which impingement and float blowing are combined to ensure high heat transfer into the web, as well as good runnability. The typical operating parameters of the air dryer are a blowing velocity of 60 m/s and an air temperature of over 400°C. It is a standard solution in Valmet’s new machine installations.

IR drying features low energy efficiency

The energy efficiency of the IR dryer is low, 25–35%, compared with the modern air dryer, where 60–80% of the heat input is absorbed by the paper web. With the electric IR dryer, most of the radiation energy tends to be absorbed by the dryer construction. Thus, 65–75% of the energy is bound to cooling air that is needed to prevent the construction from overheating. With the gas IR dryer, in turn, less than half of the gas energy can be transformed into radiation in combustion. The rest is bound to combustion gases. In addition to this only part of the radiation is absorbed by the paper web.

Energy cost of OptiDry Coat vs. IR dryers on an 8-meter-wide dryer with the same evaporation rate. Annual operating time 8,000 h/a. Energy source: natural gas. Natural gas 30 €/MWh, electric power 55 €/MWh.Energy cost of OptiDry Coat vs. IR dryers on an 8-meter-wide dryer with the same evaporation rate. Annual operating time 8,000 h/a. Energy source: natural gas. Natural gas 30 €/MWh, electric power 55 €/MWh.

Excellent surface properties with an air dryer

It has been thought that the IR dryer is a must in coating drying in order to ensure good surface properties. This is based on the knowledge that the coating color has to solidify quickly on the paper sheet after its application; thus a high drying effect is needed. However, this is no longer true. The OptiDry Coat air dryer has a higher evaporation rate than the IR dryer.

High-intensity drying right after the coating application and before the critical drying phase has a positive effect on paper quality. When you start the drying in an early phase, water drainage into the base sheet is reduced. The highest drying intensities with OptiDry Coat (450–500°C, 50–60 m/s) have given the best quality.

When air and IR drying have been compared with each other, high-intensity air drying has provided a little better smoothness and printed gloss than IR drying. This is explained by the fact that the IR dryer heats the sheet more and evaporates less, resulting in higher water drainage into the base sheet.

25-35% lower energy consumption

With OptiDry Coat as a first dryer, the total drying energy consumption in coating drying is 25-35% lower than with the traditional combination of the IR dryer and the air dryer. The gas consumption of air dryer has been 50% lower compared with the IR dryers removed from various machines. Significant savings in maintenance costs have also been gained since there is no need to change expensive lamps and radiators with the air dryer.

*) Until Dec. 31st, 2013 part of Metso Corporation