Beyond Circularity: Maximizing efficiency and minimizing waste

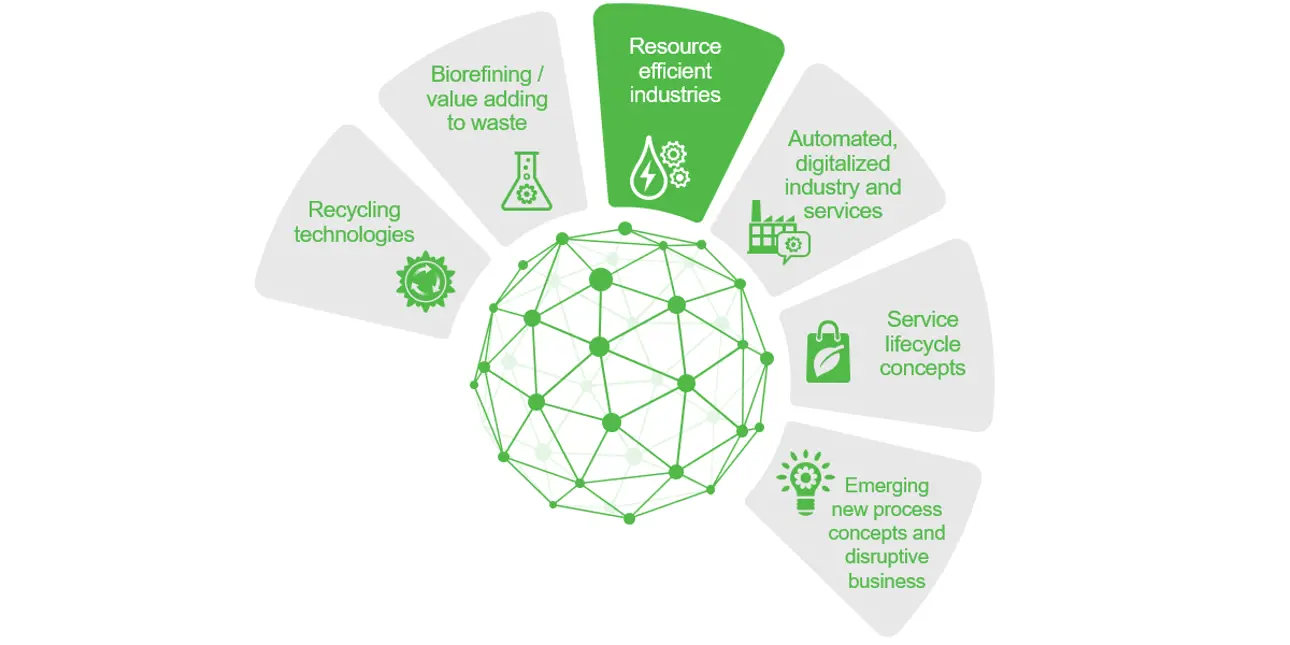

In 2022, Valmet launched an ambitious R&D program and ecosystem called Beyond Circularity. 'Resource-efficient industries' is one of its seven streams. It aims to develop solutions for maximizing efficiency and minimizing waste.

Why was 'Resource-efficient industries' selected as a stream?

“Maximizing efficiency and minimizing waste are vital circularity targets and are crucial for our customers. These topics have long been on Valmet’s agenda, so it was natural to include them in the Beyond Circularity program,” says Sampo Immonen, leader of the stream and Director, Line R&D in Valmet’s Paper business line.

Photo: Sampo Immonen spoke about the Resource-efficient industries stream at the Beyond Circularity ecosystem event in September 2023.

What kind of topics does the stream contain?

“We’re innovating and developing new technologies to find more energy-efficient solutions for our customers. We’re also developing solutions to close material loops and to utilize the low-energy heat lost in industrial processes to enhance material and water efficiency, and to use materials with a high energy content as energy storage in the industry as a part of smart electricity networks. We’re also developing sustainable new solutions for machine components,” Immonen says.

All these topics are strongly linked to Valmet’s Climate program – Forward to a carbon-neutral future and support its ambitious targets.

Research and development work is undertaken in five sub-streams:

- Energy-efficient technologies

- Raw material efficiency

- Closed water loops

- Fossil-free technology

- Sustainable machine components.

Collaborating with ecosystem partners

“Today, collaboration is even more important in product development, as we need quick solutions for the complex challenges we face. I believe the program will give a good boost to our research and development work,” says Immonen.

The stream has eight ecosystem projects, which have received funding from Business Finland and the EU:

- Co-innovation project Resilient bronze

- Co-research project POWER Beyond – Process optimization with friction- and vibrationless technologies for energy efficiency and circularity. Read more about the project

- Co-innovation project CARAMEL – Circular processes and sustainable applications for novel hard metal coatings and structures

- Co-innovation project AMAze - Additive manufacturing postprocessing automation. Read more: DIMECC's press release.

- Co-research project Emission Free Pulping aims to significantly reduce biomass burning and increase the product yield of wood material used for pulping from approximately 50% to around 70%. Read more: the article about the project and project's web page.

- Co-research project Data-driven design for sustainability

- SteamDry, an EU-funded project revolutionizing the paper industry with superheated steam drying technology. Read more on the project page in LinkedIn.

- ERDF program (EU consortium) Energy1st, energy-first fiber products forming. Read more on VTT's page.

An exciting example: POWER Beyond co-research project

Video: Air barrier load and eccentricity testing in the Aalto University laboratory

The POWER Beyond co-research project is seeking innovations and applications for frictionless aerostatic bearings, aerostatic sealing and improved vibration control. Working with Aalto University and other industrial partners, we are especially looking for ways of making paper machine rolls more energy efficient.

“A paper machine roll traditionally features oil-lubricated pads for deflection compensation, a method that requires energy because of pumping and friction. We’re exploring opportunities to replace these hydrodynamic bearings with frictionless aerostatic seal units and loading shoes that adapt to the roll’s surface and movement,” says Valmet’s Technology Manager Jyrki Huovila.

If it proves feasible, the project may result in aerostatic applications with a wide industrial appeal. Such aerostatic bearings would allow looser tolerances and would be cheaper to produce.

Another key research area is improved vibration control, which could enable higher drive speed ranges and more efficient machinery within various industries. Valmet is especially interested in improving the vibration stability of paper machine winders through active hydraulics.

The project began in 2022 and will continue into 2025. The research has already produced promising breakthroughs, and the first proof of concept with test equipment was successful in a laboratory setting.

Read more about the project.

The article was edited in June 2024: A list of ecosystem projects updated

Related articles