Beyond Circularity: Developing innovative recycling technologies with ecosystem partners

Jun 9, 2023

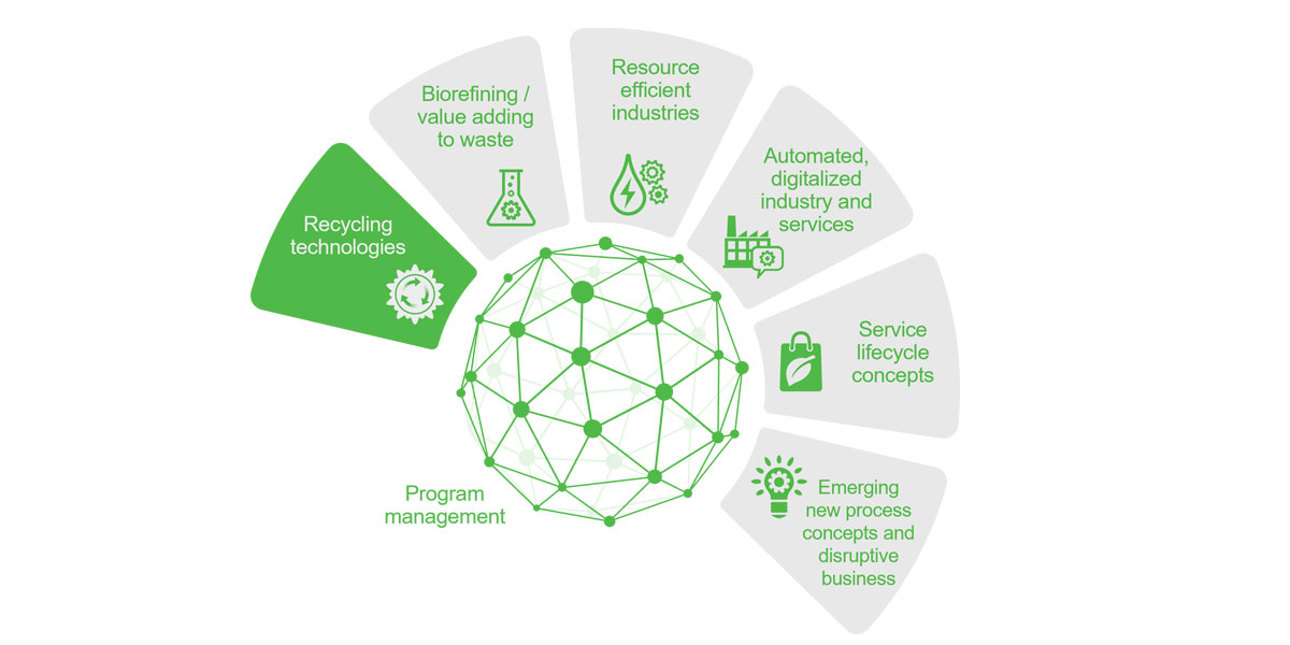

Valmet launched an ambitious R&D program and ecosystem called Beyond Circularity in 2022. It targets the transformation of waste and emissions into valuable resources for sustainable growth and to accelerate the green transition. The program is implemented through seven streams, of which Recycling technologies is one.

“A sustainable future requires a circular economy approach. The fundamental idea of circularity is embedded in Valmet’s mission: ‘Converting renewable resources into sustainable results.’ Recycling is an integral part of the circular economy. At Valmet, we have a long history of developing innovative recycling technologies, so it was natural to include it in our Beyond Circularity program,” says Henrik Wallmo, who leads the Recycling technologies stream at Valmet.

“In the Recycling technologies stream, we focus on developing recycling technologies across several areas. We’re actively working with textile, plastics and panelboard recycling, to mention some examples. We have excellent partners and inspiring and promising topics, so I’m looking forward to many exciting new solutions which will support our customers in their green transition,” Henrik Wallmo says.

Recycling is also close to Henrik’s heart in his personal life. “In my household, we always try to recycle used packaging and sort waste as much as possible. We also try to use things a second or third time. It might be simple things like an old chair becoming a bedside table. I like the idea of seeing waste or leftover materials as an asset and something you can turn into a more valuable new product."

That’s an essential part of Beyond Circularity – taking circularity to the next level, going past traditional recycling to go Beyond.

Henrik Wallmo presented Recycling stream in the Beyond Circularity launch event in November 2022.

Processes for recycling pre-industrial and post-consumer textile waste

Textiles are an essential part of our everyday life and of many industries. The downside is that the production chain creates ecological challenges, and most textile products end up as waste. Only one percent of all used clothes in the EU is recycled into new clothing, so the recycling level needs to be increased. Consumers are demanding more sustainable and ethical textiles. Technologies already exist that we can utilize – and new ones are underway. The development just needs to be accelerated, and that’s what we’re driving for with our ecosystem partners.

In the fiber-to-fiber textile recycling area, Valmet has delivered the main process equipment for Renewcell’s textile recycling plant on the Ortviken industrial site in Sweden. Renewcell produces 60,000 t/a of circulose from pre- and post-consumer polycotton textile waste to be used in viscose or Lyocell production. Read more: Recycled and Cellulose Based Textile Fibers

The Sustafit project is an ongoing co-research project which will outline segment-specific sustainability strategies for the use of sustainable and recycled fibers and their processing into non-woven products. The project builds an understanding of jointly identified knowledge gaps and sustainable fiber attractiveness for non-woven applications by developing their hydrophobicity and boosting their antimicrobial performance. Read more about the project.

New solutions for chemical recycling of plastics to enable circularity in the petrochemical industry

The plastic waste recycling rate is much too low, so we need industrially feasible chemical recycling processes which can utilize mixed plastic waste.

Valmet participates in the UrbanMill co-innovation project which is a two-year project, funded by Business Finland and coordinated by Finland’s VTT Technical Research Centre in cooperation with Aalto University. It is developing enabling technologies to utilize highly mixed plastic waste as feedstock for chemical recycling, producing high-quality plastic materials that complement the current recycled plastics. It focuses on creating novel concepts by combining tailored pre- and post-treatment technologies with pyrolysis. The project is currently in the piloting phase.

The HiPer project is another co-innovation project in this stream. This two-year project is coordinated by VTT, and nine Finnish companies are working together to take the production of new biocomposites to an industrial scale. The aim of the HiPer project is to generate a completely new product portfolio based on lightweight sustainable composite materials. These new materials will be suitable for several industrial sectors such as construction, automotive, transportation, furniture and packaging.

Read more on the project’s web page.

Resource-efficient continuous panelboard recycling process

Circular and sustainable flooring and minimizing environmental impact are trending in the panelboard industry. Currently, used Medium Density Fiberboard (MDF) materials are mostly burnt, which is unsustainable. So innovative recycling processes are needed.

In this field, Valmet has performed pilot trials with customers and carried out its own R&D trials to increase knowledge in 2022. We have also finalized an investment in new disperser and other sub-processes at our pilot facility in Inkeroinen and are moving ahead with more customer trials in 2023, using Medium Density Fiberboard (MDF).

Interested in joining our ecosystem?

Beyond Circularity aims to solve such complex and challenging problems that active collaboration with a wide range of partners is needed for success.

A green transition ecosystem is a key part of our Beyond Circularity program. Together, we can innovate, renew and enable our customer industries in the switch to carbon neutrality and to facilitate the green transition.

“We already have more than 80 ecosystem partners and 12 joint projects, funded by Business Finland and the EU. In the Recycling stream, we have 41 partners, with three joint projects granted in 2022 and a good number of ongoing internal and other R&D projects,” says Virpi Puhakka, Director, Ecosystem at Valmet.

If you are interested in ecosystem partnering, please see more information from our Beyond Circularity page.

If a joint project is accepted for the Beyond Circularity ecosystem (with Valmet approval), Finnish partners may submit a partnership funding application to Business Finland. Business Finland offers partnership funding for research, development and innovation projects under the ecosystem themes of the Beyond Circularity program.