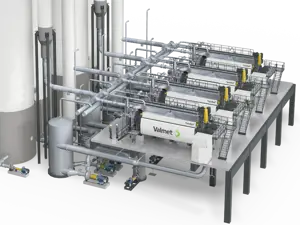

Valmet TwinRoll Press

The TwinRoll Evolution is the fifth generation in a line of twinroll presses first introduced over 60 years ago in 1954. The presses are unique in combining Valmet’s proven machinery, process know-how, and state-of-the-art automation. Valmet TwinRoll Press takes dewatering and washing to a new level by increasing capacity by up to 30 percent, improving consistency, and optimizing operation while minimizing operational and maintenance costs.

Increased capacity

The increased capacity in the TwinRoll Evolution presses starts at the top. The new pulp inlet arrangement allows pulp feed with a very small feed pressure. The new design reduces energy consumption and creates flexibility in the installation. From here, the pulp drops into the patented RotoFormer, designed to distribute and form the pulp for optimal consistency and throughput. Considerable attention was devoted to the design of this stage. Mathematical flow analysis was used extensively and enabled pulp consistency to be increased to as much as 10–11 percent. A further innovation in the TwinRoll Evolution derives from top feeding, which allows the press to be utilized for a greater portion of its rotational cycle. This gives increased press time thus significantly improving washing efficiency and higher production levels. Finally, the proven vat design with a parallel gap between the roll and the vat, gives even and stable pulp flow throughout the whole capacity range

Variable nip – bringing washing to a new level

The core feature and the greatest innovation in the TwinRoll Evolution series is the variable nip. The nip is the stage at which the final dewatering takes place and is normally fixed during operation. In the TwinRoll Evolution, however, the nip can be varied to optimize the operation. This is the key to bringing washing to a new level in Valmet’s fifth generation press.

Built-in reliability and easy maintenance

Reliability and ease of maintenance were important considerations in the development of the TwinRoll Evolution. Although the press rolls, bearings, and seals are identical in nearly all respects to previous generation presses, they have been enhanced in a number of minor but significant ways to increase reliability. In addition to these enhancements, the seals and bearing housings are now separate, and the bearings are oil-lubricated for longer life. They are also highperformance CARB bearings.

The most striking difference in the TwinRoll Evolution, compared with previous generations, lies in the modularly designed flaps on the middle section. These flaps fold out for maintenance with selfrestraining actuators that function as locks for the flaps using a common motor.

The flap can be opened 10 degrees for service from the grate at the top of the machine, and opened 40 degrees for access to internal components.

This provides full and easy access for service of seals, and cleaning and inspection of rolls. With the flaps open, maintenance personnel also have full access to service points for motors and other components.

While ease of maintenance was a primary concern in designing the modular flaps, they also contribute to saving space and lowering costs. Because virtually all serviceable components are accessible from the upper grate and by opening the flaps, there is little need for platforms around the press. In fact, in many installations, only a single platform is needed for access to the machine.

Clean and cost-efficient installation

Reducing the number of platforms required around the press is not the only space-saving feature of the TwinRoll Evolution. Top feeding with low inlet pressure even at high feed consistency results in a very compact and energy efficient installation

A unique tradition to rely on – today and tomorrow

Valmet’s goal in developing the TwinRoll Evolution was to keep the best features that made previous generations the industry’s best-selling twin-roll press, while leveraging a decade of advances in technology to deliver capacity and cost-efficiencies that will keep its customers competitive today and tomorrow.

In developing the TwinRoll Evolution press, Valmet has minimized operational and maintenance costs and increased capacity and washing efficiency while maintaining high feed consistency. The TwinRoll Evolution presses offer a high degree of safety for personnel, a wide capacity range, and automated systems for optimum operation. The TwinRoll Evolution presses thus refine a unique tradition in combining Valmet’s proven machinery, process know-how, and state-of-the-art automation. At the same time, they take dewatering and washing to new levels that will redefine industry standards for performance and efficiency.

Our expertise is at your service

Our focus is to bring your performance forward utilizing our extensive experience and in-depth knowledge of pulp process technology. Get in touch with our experts through your local Valmet office, or the link below.

Contact us