Process upgrades for wood processing equipment

Maximize wood usage efficiency and increase wood material yield by process and equipment upgrades

As a leading technology expert in woodhandling we have extensive expertise and experience. This knowledge is incorporated in all our products, giving us exceptional insight into all aspects of upgrading your debarking, chipping, chip screening equipment for more efficient wood usage.

Efficient wood usage

Profitable investments with a short payback time

Easy and reliable operations

Wide range of upgrades available to increase competitiveness

Our skilled experts gives you the right recommendations for improvements for your needs. Looking to improved capacity and quality while maintaining or increasing competitiveness. With latest upgrades and technologies, materials and designs, smart automation upgrades and solutions help reach these targets. Benefits include production cost savings, improved runnability and higher availability of automation equipment.

For the Debarking process we can offer:

- Detects unknown particles in the material flow e.g. stones, metal pieces and lumps of ice with SoundTrap

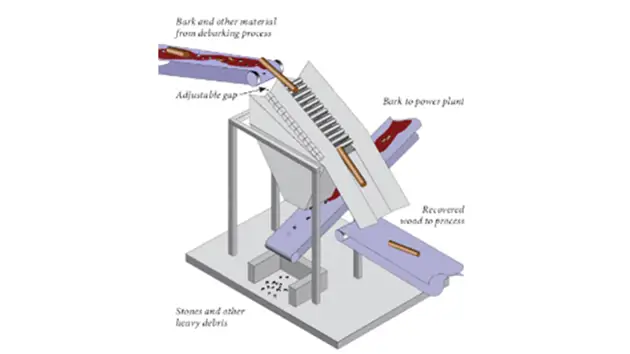

- Wood Saver is special roll conveyor system designed to maximize wood usage efficiency in debarking lines

For the chipping process:

- Occupational safety with chipper knife changing device Valmet Easy Turn

- Chipper Thrust Bearing system for disc chippers

- Durable Chipper Hood a technology based on an extremely hard-faced hood wrapper in all areas subject to wear

- Safer maintenance of your chipper Chipper disc safety locking device

- Easy maintenance and user friendly solution for Carthage Chippers Carthage Knife Clearance Setting Device

- Maintenance can be done without removing the feed chute Split Spout

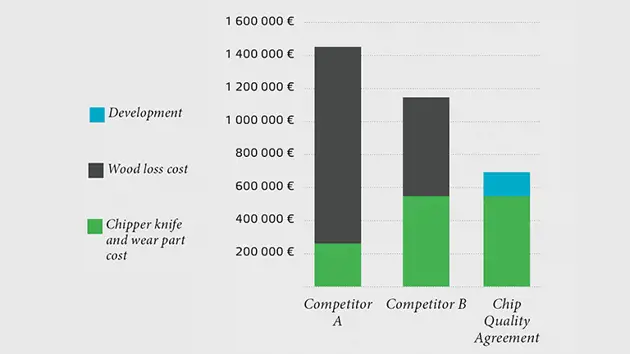

- Improve your process from the beginning Chip Quality Agreement

- Innovative knife fastening system with a single bolt Quick Fastening

- Chipping speed control system Valmet Chipping Speed Control

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usCustom-made chip quality optimization

Valmet provides custom-made Chip Quality Agreements (ChipQ) depending on customer’s process equipment and requirements. The process starts with wood receiving and covers debarking, chipping, storage, and screening. The primary target of the optimization is even chip quality and minimized wood losses. Valmet will help to achieve optimum quality while providing the tools for optimizing your process and production economy.

Reduces wood losses from screening and debarking

- Reduces 0-mass production and chemical/energy consumption (lower fines content)

- Reduced wood consumption

- Reduces raw material-based downtime in the whole mill

- Enables more uniform chip thickness and therefore more uniform end product quality – lower variation

Read more about Chip Quality Agreements

Chip screening upgrades:

- Less chip screen downtime with a special coating eliminates blocked screen-plate holes NanoPlate

References and articles

keyboard_arrow_leftBack

{{currentHeading}}

{{productForm.Name}} {{"("+productForm.Size+")"}}