Hydro turbine automation

Valmet's solution enables efficient hydro turbine management, improves operational cost efficiency and simplifies system maintenance.

Automation solutions

Hydro turbine automation

Valmet's solution enables efficient hydro turbine management, improves operational cost efficiency and simplifies system maintenance.

Automation solutions

Steam turbine performance monitoring

Valmet DNA Steam Turbine Performance Monitoring brings increased efficiencies and cost savings to each step of turbine operation.

Automation solutions

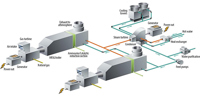

HRSG and plant controls for combined cycle power plants

Valmet DNA system covers the control, monitoring and reporting of all processes in combined cycle power plant.

Automation solutions

Automation retrofits

Retrofitting an existing automation system with Valmet DNA DCS to boost the power plant’s total efficiency.

Automation solutions

CO2 Monitoring

Valmet DNA CO2 Monitoring reports to the EU Emission Trading Directive (2003/87/EC) generating automatically all the necessary information.

Automation solutions

Copelme leverages Valmet's MyGo technology to boost its production capacity

Building on the success achieved with Valmet’s advanced Perini Constellation™ technology, Copelme continues to invest in Valmet's technological solutions to strengthen its competitive position in the sector. Specifically, the choice of this line is due to its modularity, sustainability, and safety – qualities that add significant value to support customer's growth ambitions

Insights ● Article

Stonel™ visual indicator

Clearly view valve position status from up to 75 feet with Stonel stand alone visual Indicator. The indicator’s rugged polycarbonate construction makes the indicator resistant to physical damage and tolerant to most corrosives.

Flow control

Stonel™ Eclipse™ compact limit switch

The Stonel Eclipse features dual solid state sensors with optional communications neatly integrated into a sealed module. The Eclipse series is available in (3) form factors to meet your application needs. The NEW ultra compact version for general purpose applications (EC), non-incendive and intrinsically safe versions (EN) for hazardous areas with a removable module and in a general purpose, completely sealed, micro-connector version (EG). For networking/wireless link capability, select EC series.

Flow control

3 steps to ensure ESD valve reliability beyond certification

Final elements, such as ESD valves, are a critical part in the safety lifecycle. When they are not working properly, the safety of the entire plant is in jeopardy. To ensure overall plant safety, correct ESD valve selection plays a vital role. A lot of uncertainty prevails around the relatively new standards IEC 61508 and IEC 61511 and how they should be interpreted for safety valves. This blog post looks closer at this issue and sheds some light on what is an essential but confusing subject.

Insights ● Blog post

Field services for pulp drying equipment

Different problems need different solutions. By supplying expert maintenance services and comprehensive support tailored for each customer, we ensures efficient pulp drying operation with minimal downtime, improved performance, and increased output. We can support the needs through different services such as field service site support, remote support via our Valmet Performance Centers and onsite troubleshooting and audits. Our long experience and knowledge as a pulp dryer machine supplier provides a special know-how to ensure customer trouble free operation not only to our machines but also the complete process from wet end, drying section, cutter layboy and system function including headbox, wire section, press section, dryer and cutter.

Services