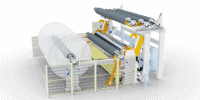

OptiSizer Hard sizing

OptiSizer Hard is uses higher nip loads to improve sheet strength properties by taking advantage of better starch penetration and decreasing fiber to fiber distance.

Board and paperFilters

OptiSizer Hard sizing

OptiSizer Hard is uses higher nip loads to improve sheet strength properties by taking advantage of better starch penetration and decreasing fiber to fiber distance.

Board and paper

OptiCalender Soft nip calendering

Valmet's soft nip calenders are well suited for final calendering of different types of board, newsprint, and fine papers. Another area of application is pre-calendering of coated paper and board.

Board and paper

OptiReels without center drives

OptiReel Pope and Linear without center drives are Valmet’s standard reels. They provide just the right level of reeling technology required by grades and operations with less demanding reeling conditions - especially suitable for containerboard and uncoated fine paper grades.

Board and paper

IntelliReel

The IntelliReel structure enables easy control over the reeling process. It lets to wind a paper precisely, repeatably, efficiently and safely. A uniform parent roll is obtained and ready for converting operations by the end of reeling process. IntelliReel benefits include: controlled nip throughout winding process, minimized winding defects and sheet losses, easy process control, safe and minimized maintenance and it can be a tailor made solution. In the optimum parent roll structure building the purpose of nip relieving is to reduce the excessive weight of the spool and thus control the nip load between the spool and reel drum.

Board and paper

Increase capacity

There are several ways to increase the production of a paper or board making line. The paper machine's efficiency can be improved for example by decreasing the number of breaks and shortening the break time. Drying capacity can be found to be a bottleneck. Drying capacity can be increased by solutions that maximize drying efficiency with minimum energy consumption. Machine speed can be limiting production, too.

Board and paper

Improve quality

Quality issues are high on the agenda of every paper and board mill, as optimal quality needs to be produced at the lowest possible cost. Valmet offers a wide scope of solutions and services for better end-product quality, from stock preparation to finishing. Stabilizing running processes in all phases of the process leads to cost-effective quality improvements that do not require major investments. We and our customers share the same targets: optimal quality at the lowest possible cost, consistently in all shifts.

Board and paper

Cylinder drying

In papermaking, it is vital to ensure maximum drying efficiency with minimum energy consumption. Valmet cylinder drying portfolio is able to provide perfect solutions for all customer needs regardless of your grade, machine speed, or basis weight. Our offering also includes rebuilds, components, and services, in addition to various drying analyses and optimization services.

Board and paper

OptiSizer Combi sizing

OptiSizer Combi combines different size application methods in one process to benefits of both technologies when paper top and bottom sides have completely different needs.

Board and paper

OCC Lines

Every day, millions of people receive packages. And the amount keeps rising rapidly. That’s why we can’t rely on the invaluable virgin materials.

Board and paper

Bale Tester

Valmet Bale Tester is an equipment with measuring device that has a drill which penetrates to the bale on a truck, making a hole in it and extracting the sample from the bale.

Board and paper