Wet streak caused by corrosion of roll shell, case study

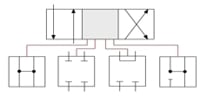

A wet streak leads to combined investigation by mill personnel and Valmet roll specialists. A suction roll cover is removed and analyzed, after which a metallurgist inspects the roll. The mill mechanic provides a key insight...

Insights ● Article