Yinzhou Paper's rebuild for better quality test liner

Frequent customer complaints regarding the evenness and CD profiles of Dongguan’s linerboard led Yinzhou Paper to replace the headboxes and invest in modern quality control system.

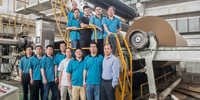

Insights ● Article