Roll types

Services

Roll types

Services

Chip treatment

The chip pretreatment stage is a key process in all mechanical pulping processes. Valmet is the market leader, offering the best solutions in terms of pulp quality, flexibility, availability and cost per ton.

Pulp

Valve products

To help you optimize your process performance and reliability, Valmet approaches each process and application as a specific challenge. Our control, on-off and ESD valves, accessories, intelligent devices and software products are engineered to meet these challenges. They provide innovative, fundamentally simple construction, operation and maintenance features to optimize process performance at the lowest cost.

Flow control

CFB boiler optimization

CFB boiler operation and optimization based on understanding the function and processes of the boiler.

BFB boiler optimization

Optimizing the BFB boiler based on understanding the function and processes of the boiler.

Grate fired boiler

Grate boiler operation based on understanding the function and processes of the boiler.

Continuous Cooking G2

The main purpose of the cooking plant is to free the wood fibers and separate the lignin.

Oxygen delignification

In the oxygen delignification course you will learn about the function of the oxygen delignification stage and about the machines that are included

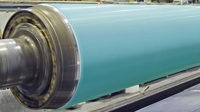

Calender roll covers

Targeting long grinding intervals and smooth surface quality? Valmet’s calender roll covers provide longer service intervals and optimum paper or board properties. Besides providing better marking resistance, our calender covers allow much higher speeds and temperatures without damage than conventional alternatives. For paper and boardmakers these factors mean quality. Let Valmet help you to run with the most suitable cover for your calender.

Services

Winder drum covers

Valmet’s soft roll covers for winding applications provide good wear resistance and durability for high speed winding, resulting in long running times and high production levels. The hard thermal coatings for winder drums are even applicable on-site, with no need to remove the drum from the winder.

Services