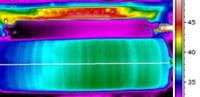

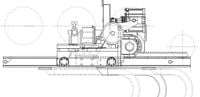

How to troubleshoot calender roll heat transfer problems

The following were noted during installations and are common installation troubles. Read them carefully to rectify or avoid them during your installation.

Insights ● ArticleFilters

How to troubleshoot calender roll heat transfer problems

The following were noted during installations and are common installation troubles. Read them carefully to rectify or avoid them during your installation.

Insights ● Article

Field services for optimized reliable stock preparation

Maintenance of stock preparation and approach flow systems optimizes their utilization rate and reliable operation, and minimizes unplanned shutdowns.

Insights ● Article

Five best practices for roll performance and cover life

For optimum performance and to maximize cover life, keep covers clean, monitor and avoid high cover temperatures, check crown and avoid impact damage.

Insights ● Article

Maintenance and operation of press stretchers and guides

The paper machine has a number of various loop-type fabrics, wires and felts, which must have a specific tension and controlled position in the cross direction of the paper machine (usually in the middle) so that the paper machine operates properly and as designed.

Insights ● Article

Common ways an OEM partner helps mills achieve their goals

Maintaining a strong relationship with a trusted OEM partner lets producers learn from the industry’s manufacturing legacy and keep operations moving forward.

Insights ● Article

Reeling parameters - tension, nip load and peripheral force

The three critical parameters which must be controlled to make a well structured parent roll that can handle further processing are determined case-by-case.

Insights ● Article

Valmet iRoll Portable Press Analysis at Cartiere del Garda

Cartiere del Garda used Valmet iRoll Portable Press Analysis to resolve problems with moisture profiles, felt lifetimes and more.

Insights ● Article

The mechanics, factors and prevention of size press orange peel

A common problem on film metering size presses is orange peel. Orange peel is caused when the coating film splits away from the coated sheet in the immobilized coating layer at the exit of the size press nip.

Insights ● Article

Pilot trials - a reliable basis for successful business decisions

Mills use Valmet's Technology Centers for a selection of testing and pilot services which help eliminate risks related to business investments and decisions.

Insights ● Article

Valmet Belt Roll Doctor reduces press moisture, a case study

A 1990s uncoated freesheet machine in the United States wanted to decrease their press moisture. They chose the Valmet Belt Roll Doctor to doctor the shoe press belt.

Insights ● Article