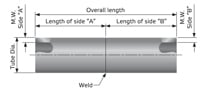

Dissimilar metal weld inserts

Services

Dissimilar metal weld inserts

Services

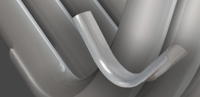

370° Tube Shields

Services

Custom Curved Sheilds

Services

Climate-friendly Bioethanol from agricultural waste at Clariant in Germany

The Swiss speciality chemicals company Clariant, inaugurated Germany's largest second-generation bioethanol plant in July 2012. The cellulosic ethanol produced by Clariant reduces CO2 emissions by 95% compared to fossil fuels, and it does not interfere with food or feed production. The raw material is agricultural residue such as wheat straw or corn stover.

Flow control for construction

Reliable flow control for cement handling is crucial. Our abrasive-resistant Flowrox™ slurry pumps, control and shut-off valves are therefore ideal for construction industry.

Mechanical Seals

To minimize the environmental impact Valmet has developed a new mechanical sealing system including double acting seals and closed loop water system which minimizes the water that enters the process. With this function you save fresh and waste water which results in reduced water costs and thermal energy savings due to less water to evaporate in the dryer.

Food industry

Flow control and automation solutions for food and beverage.

Flow control for food and beverage

Meeting increasing demand while maintaining safety is a key factor in the food and beverage industry.

Clothing/padding for chest ironers and presses

Services

Flow control for floating LNG

Valmet's compact and high performance valves and flow control services offer floating LNG plants long lifecycle and trouble-free operations.