Mill finds good housekeeping can reduce vibration, case study

PM5 was producing waves of vibration that speed limited the machine, reducing production by 10%. Vibration analysis pointed to the gearbox pinion shafts.

Insights ● Article

Mill finds good housekeeping can reduce vibration, case study

PM5 was producing waves of vibration that speed limited the machine, reducing production by 10%. Vibration analysis pointed to the gearbox pinion shafts.

Insights ● Article

10 tips: Resist headbox corrosion in maintenance & operation

Corrosion can be minimized by adhering to these maintenance and operating procedures.

Insights ● Article

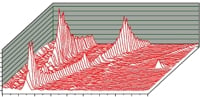

An introduction to troubleshooting with vibration signatures

The moment an asset is placed in service it is headed towards failure. It is the vibration analyst with tools and techniques, who helps prevent costly downtime.

Insights ● Article

Understanding coating viscosity, rheograms and rheology problems

Coating rheology is measured with low shear and high shear viscosity instruments. In coating rheology, viscosity is the measure of the resistance of a coating formulation to an imposed flow.

Insights ● Article

Press fabric monitoring explains machine operating performance

Good press felt monitoring and conditioning methods help avoid runnability and quality problems. There is no single approach - but some of the best practices are described in this article.

Insights ● Article

Winding principles part 3 - drum torque control methods, summary

When web tension and drum nip pressure are constant, drum torque will assure uniform or diminishing roll hardness from the core toward the outside of the rolls.

Insights ● Article

Winding principles part 2 - effect and elements of nip pressure

The relationship between rider roll pressure and shipping roll hardness is neither simple nor direct. This second article in the Winding Principles series explores the interrelationship between rider roll pressure, relief pressure, roll weight and nip load.

Insights ● Article

Floor protection in recovery boilers with decanting floors

Optimizing both the floor protection methods and materials and the cooling, washing and cleaning practices can yield significant savings in mill outage time and corresponding increases in mill production and reduced risk of mechanical damage due to mechanical cleaning or hydro blasting during floor cleaning.

Insights ● Article

Keys to optimize drying efficiency; start with the felt tension

Increased felt tension can optimize drying efficiency and improve paper quality. However, a thorough evaluation of machinery and close monitoring of felt tension, along with a complete maintenance program, are the keys to a headache-free dryer section.

Insights ● Article

Reel primary arm nip relief methods reduce bottom waste at turnup

Excessive bottom waste occurs during turn-ups where there is insufficient primary arm nip relief at the reel. To avoid this, primary arm nip force control should start before turn-up and continue smoothly as the building parent reel travels down along the reel drum to the secondary arms at the kickout rails.

Insights ● Article