Valmet Membrane Tube Panels

Services

Valmet Membrane Tube Panels

Services

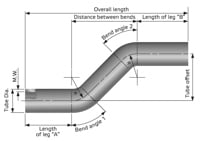

Valmet Offset Tubes

Services

Automation for biofuels and biomaterials

Valmet's automation offering is aimed at increasing efficiency and uplift in production. Through our expertise, we provide seamless integration and upgrades, for a long lifecycle approach to automation.

Automation solutions

The highest level of automation through integration of visions and solutions

Valmet Automation delivered the control system for the fourth production line at the Neste Porvoo refinery. This automation project was so far the most extensive at the Porvoo site, and included a great deal of development related to quality and safety. A clear vision based on the strong automation know-how at the Porvoo site had an important role in the planning and implementation of a system, which features the highest level of automation.

Flow control for chemical industry

Valmet has wide experience in flow control solutions for the chemical industry. We cover the entire life cycle of processes, including new installations, rebuilds and services.

Flow control for ethylene and propylene processing

Steam cracking plants, which produce ethylene, are divided into three sections which together represent a very demanding environment. Propane dehydrogenation uses propane to produce high-quality propylene. Our valves offer the highest reliability throughout every step of the demanding process.

Automation for construction

Valmet's automation offering is aimed at increasing efficiency and uplift in production. Through our expertise, we provide seamless integration and upgrades, for a long lifecycle approach to automation.

Chip Bin

The chip bin acts as a buffer and it will also heat the chips with steam and secure good feeding of the raw material to the plug screw feeder. Valmet have developed a new type of chip bin to secure even and effective heating of the chips as well as provide good feeding to the plug screw feeder. Valmet chip bin's is also suitable to handle recovered steam coming from e.g the steam separator.

Plug screw feeder

The plug screw feeder feeds the raw material, into a pressurized preheater (or digester). The feeder should remove as much water, together with extractives as possible. This is the key to reduce production costs like steam consumption, dryer energy as well as environmental impact by reducing VOC (Volatile Organic Compound) emissions in the dryer.

Automation for food and beverage

Valmet's automation offering is aimed at increasing efficiency and uplift in production. Through our expertise, we provide seamless integration and upgrades, for a long lifecycle approach to automation.