FCCU in today’s refineries

Fluid Catalytic Cracking process is one the most profitable and flexible processes in today’s petroleum processing.

Insights ● Blog post

FCCU in today’s refineries

Fluid Catalytic Cracking process is one the most profitable and flexible processes in today’s petroleum processing.

Insights ● Blog post

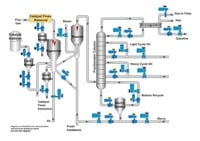

Things to consider in valve selection for catalytic cracking

Reliable and accurate control, on-off and ESD-valve performance is important for total process efficiency, productivity and safety. Here’s presented some of the key-applications and things to consider in selecting valves for a typical FCCU.

Insights ● Blog post

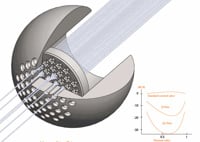

Keep the noise down - Rotary valve noise abatement in gas and steam flow control applications

Noise can be a problem in even low and medium pressure steam applications, resulting in issues like heavy vibrations or health, safety and environmental hazards.

Insights ● Blog post

Butterfly valve installed, problem solved - Reducing Dow’s operational costs under extreme process conditions

The Dow Chemical Company has been operating in Stade, Germany for more than 40 years. Nearly three million tons of basic and specialty chemicals are manufactured per year in this ultramodern integrated plant complex, placing high availability and safety demands on all components. That’s why Dow has installed a custom-designed butterfly valve, developed by Neles, to reliably shut off the DME reactor in Stade.

Insights ● Blog post

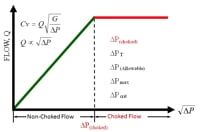

Estimating liquid vapor pressure for control valve sizing purposes

Included in the process of sizing a control valve for liquid service is the requirement for determining if flow will be choked.

Insights ● Blog post

Intelligent solenoid valves: slash time and costs with knowledge

When a refinery in South America was approaching its scheduled three-year maintenance shutdown, it decided to take advantage of the information provided from its intelligent solenoid valves. Earlier, the refinery had decided to install these valves on every emergency shutdown (ESD) valve to identify degradation by using partial stroke testing (PST) for these critical valves.

Insights ● Blog post

Increase polymerization process efficiency with reliable valves

Petrochemicals have seen tremendous growth in the last decades and many studies suggest that there will be an increasing focus on petrochemicals in the future as well. While the Covid-19 pandemic impacted the demand in the industry, it also saw a surge in the usage of polymers for example in the medical and packaging industry. Demand for masks, personal protective equipment’s, etc. increased while demand in e-commerce and many people preferring packed foods increased demand in the packaging industry.

Insights ● Blog post

How to use data to better understand your equipment

If you’re like many of our other customers, you may be worried about two things – gaining a better understanding of the condition of your equipment, and making your plant more reliable, efficient and safe. They know how to get the best performance from their plants, they need a lot of data. And you may be thinking about that too.

Insights ● Blog post

Sustainable bioproducts deserve sustainable processes

Sustainability is one of the driving megatrends in industry today. For the pulp and paper industry, sustainability has become an integral part of not just the sourcing, manufacturing and shipping processes, but also the portfolio of marketable end products being made. New bioproducts are being produced at modern mills around the world.

Insights ● Blog post

Valmet butterfly valves deliver versatility and performance for severe service applications

Their compact and lightweight design, availability in larger sizes and easy usability make our butterfly valves an attractive option for many industrial processes. Their versatility makes them suitable for a wide range of temperatures, pressures, industries, and applications. They can be used in either control, on-off or emergency shutdown service.

Insights ● Blog post